Gear dimensions are determined in accordance with their

specifications, such as Module (m), Number of teeth (z), Pressure angle

(α), and Profile shift coefficient (x). This section introduces the

dimension calculations for spur gears, helical gears, gear rack, bevel gears, screw gears, and worm gear

pairs. Calculations of external dimensions (eg. Tip diameter) are

necessary for processing the gear blanks. Tooth dimensions such as root

diameter or tooth depth are considered when gear cutting.

(1) Standard Spur Gear

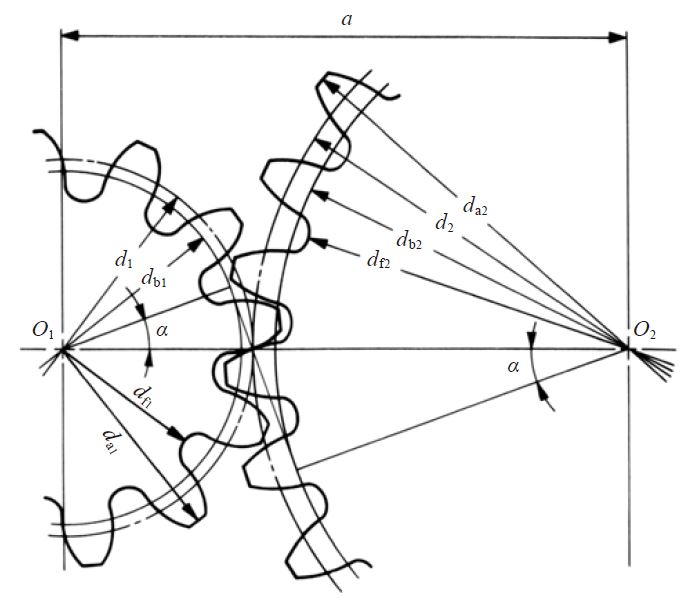

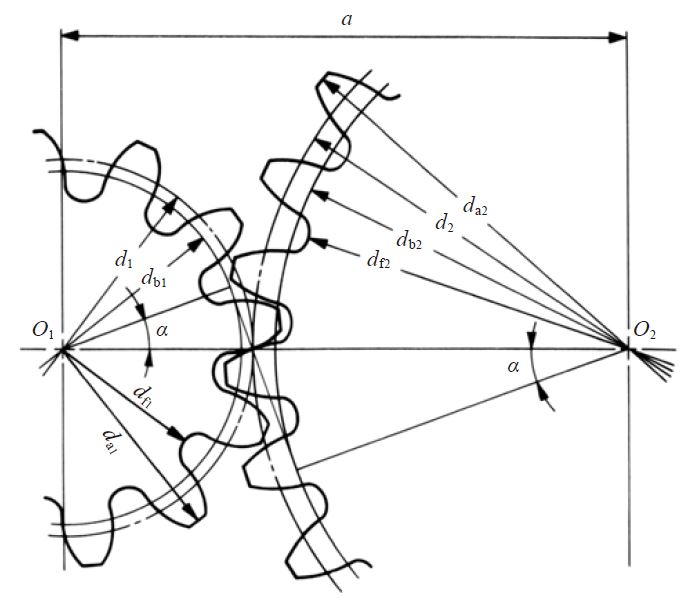

Figure 4.1 shows the meshing of standard spur gears. The meshing of standard spur gears means the reference circles of two gears contact and roll with each other. The calculation formulas are in Table 4.1.

Fig. 4.1 The Meshing of Standard Spur Gears

( α = 20°, z1 = 12, z2 = 24, x1 = x2 = 0 )

Table 4.1 Calculations for Standard Spur Gears

NOTE 1 : The subscripts 1 and 2 of z1 and z2 denote pinion and gear

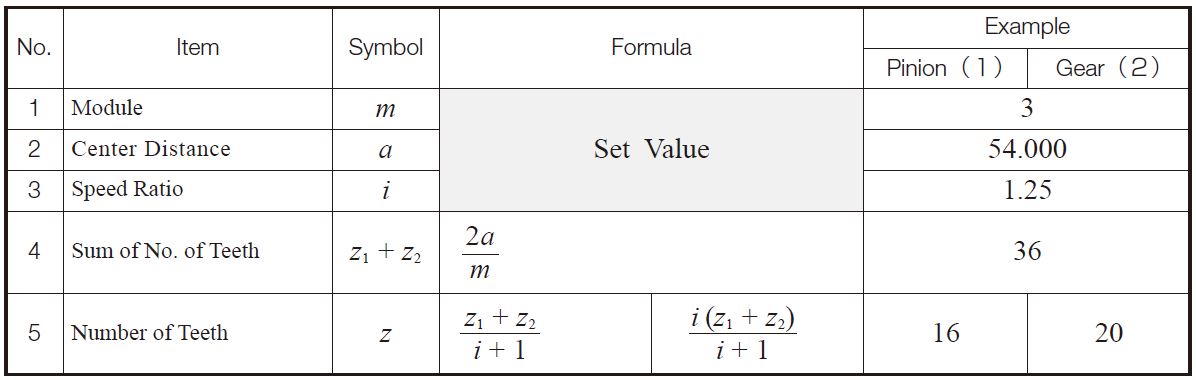

All calculated values in Table 4.1 are based upon given module m and number of teeth (z1 and z2). If instead, the module m, center distance a and speed ratio i are given, then the number of teeth, z1 and z2, would be calculated using the formulas as shown in Table 4.2.

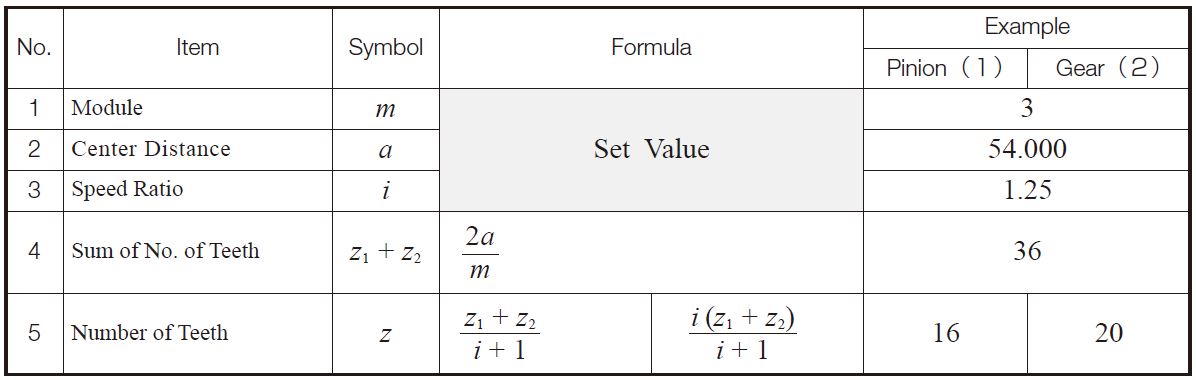

Table 4.2 The Calculations for Number of Teeth

Note, that the number of teeth will probably not be integer values when using the formulas in Table 4.2. In this case, it will be necessary to resort to profile shifting or to employ helical gears to obtain as near a transmission ratio as possible.

(2) Profile Shifted Spur Gear

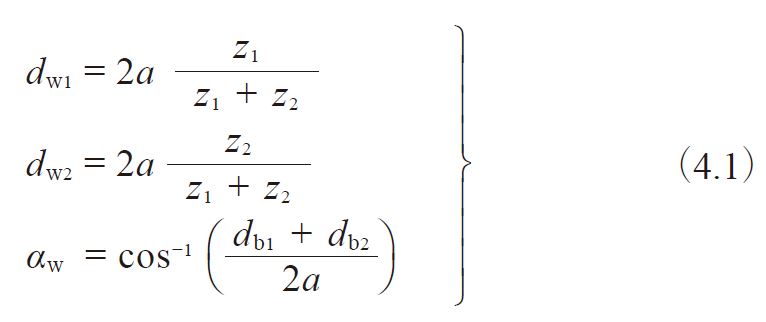

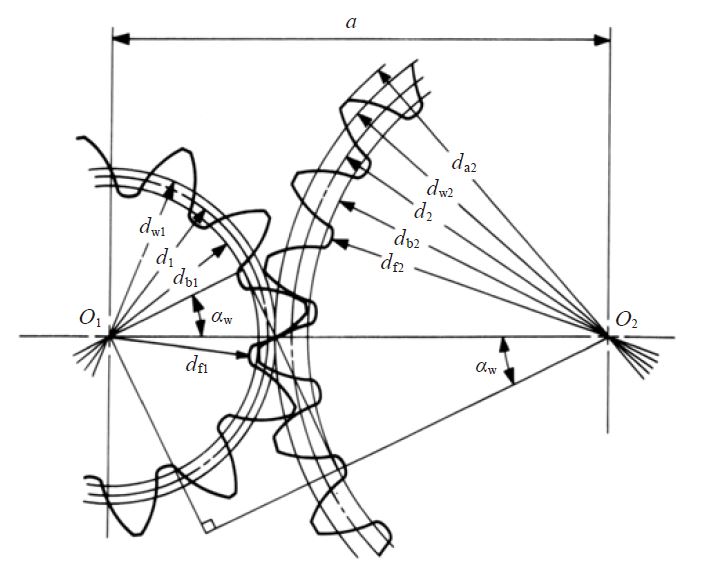

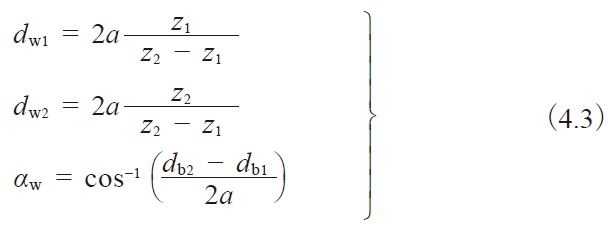

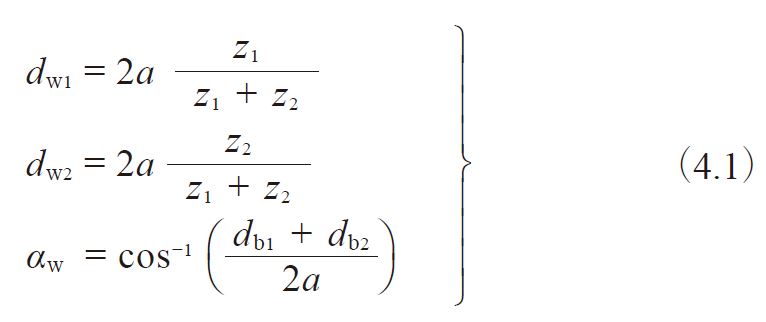

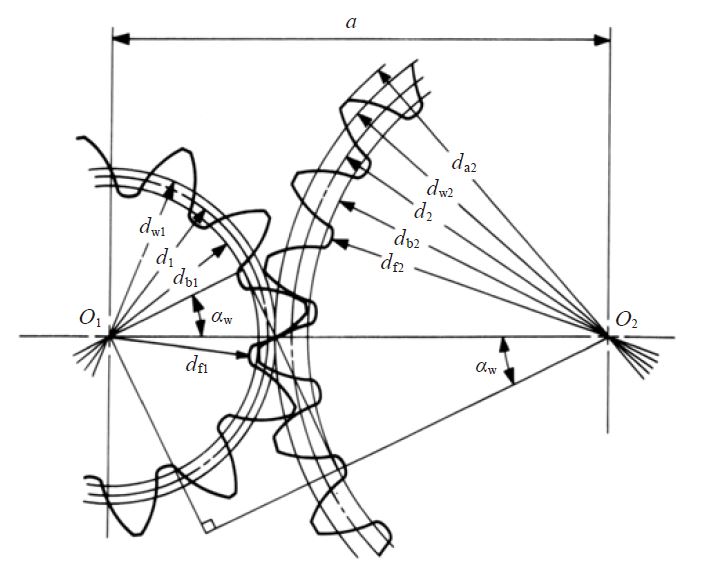

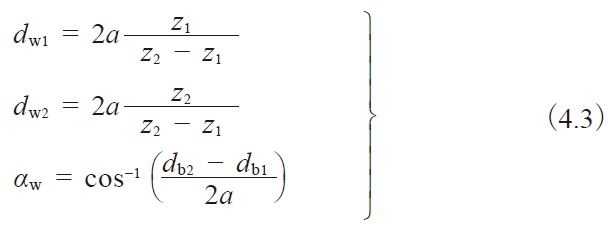

Figure 4.2 shows the meshing of a pair of profile shifted gears. The key items in profile shifted gears are the operating (working) pitch diameters (dw) and the working (operating) pressure angle (αw). These values are obtainable from the modified center distance and the following formulas :

Fig. 4.2 The Meshing of Profile Shifted Gears

( α = 20°, z1 = 12, z2 = 24, x1 = +0.6, x2 = +0.36 )

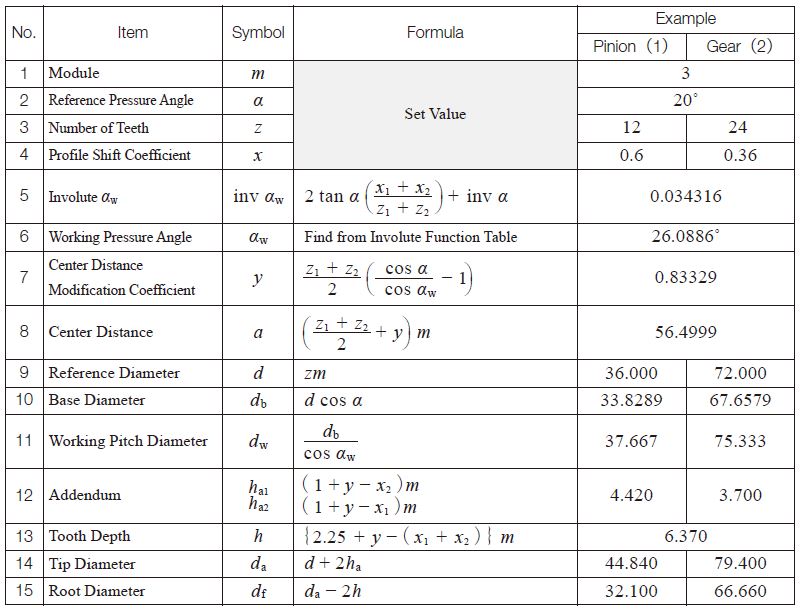

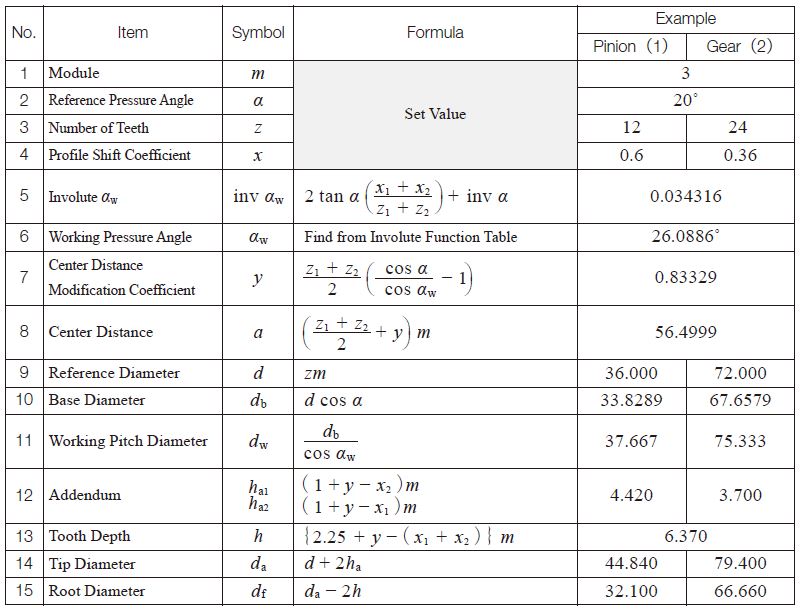

In the meshing of profile shifted gears, it is the operating pitch circle that is in contact and roll on each other that portrays gear action. Table 4.3 presents the calculations where the profile shift coefficient has been set at x1 and x2 at the beginning. This calculation is based on the idea that the amount of the tip and root clearance should be 0.25m.

Table 4.3 The Calculations for Profile Shifted Spur Gears (1)

A standard spur gear is, according to Table 4.3, a profile shifted gear with 0 coefficient of shift; that is , x1 = x2 = 0.

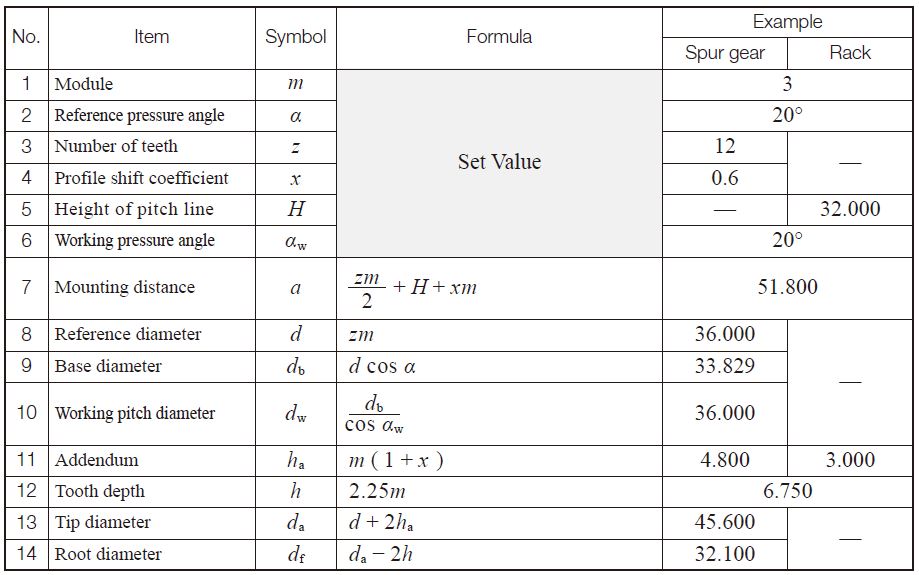

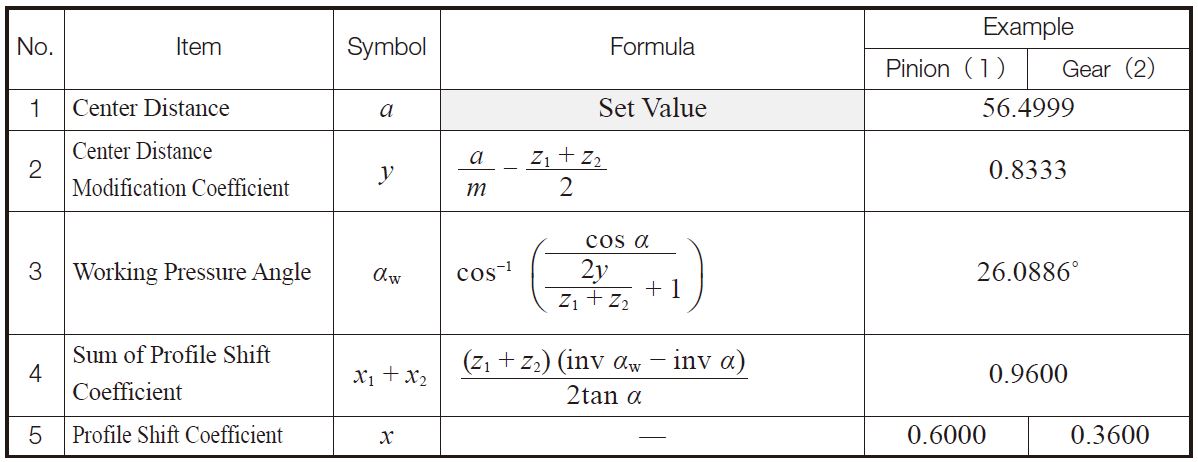

Table 4.4 is the inverse formula of items from 4 to 8 of Table 4.3.

Table 4.4 The Calculations for Profile Shifted Spur Gears (2)

There are several theories concerning how to distribute the sum of profile shift coefficient (x1 + x2) into pinion (x1) and gear (x2) separately. BSS (British) and DIN (German) standards are the most often used. In the example above, the 12 tooth pinion was given sufficient correction to prevent undercut, and the residual profile shift was given to the mating gear.

(3) Rack and Spur Gear

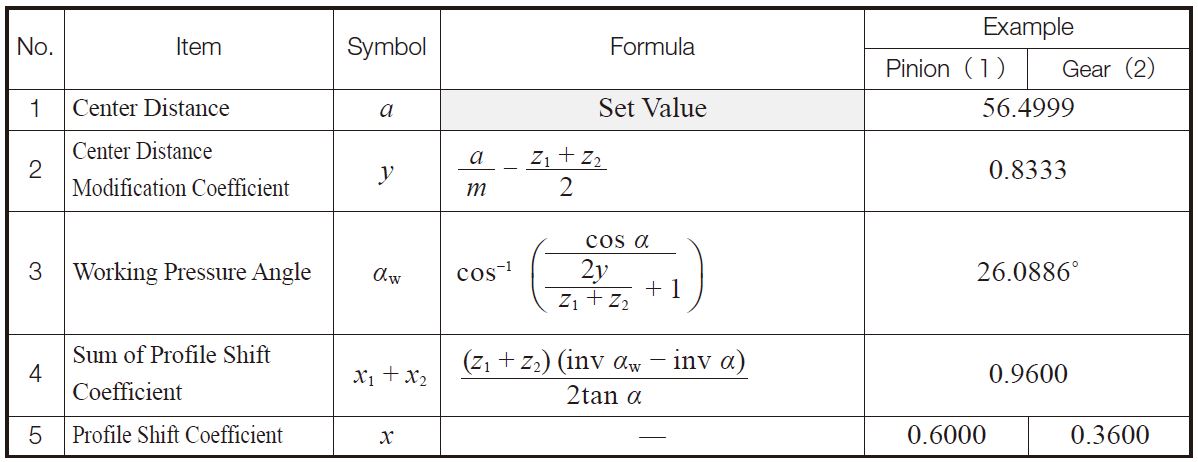

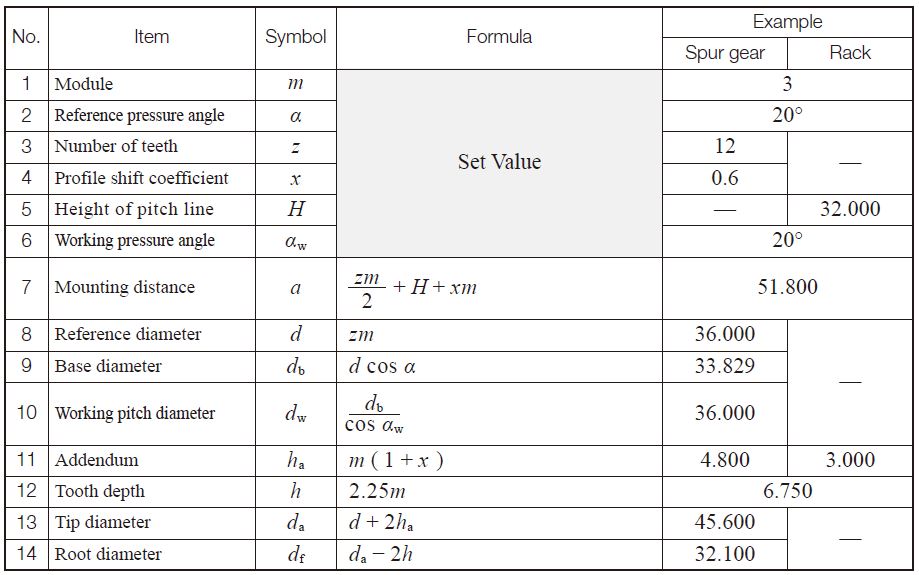

Table 4.5 presents the method for calculating the mesh of a rack and spur gear.

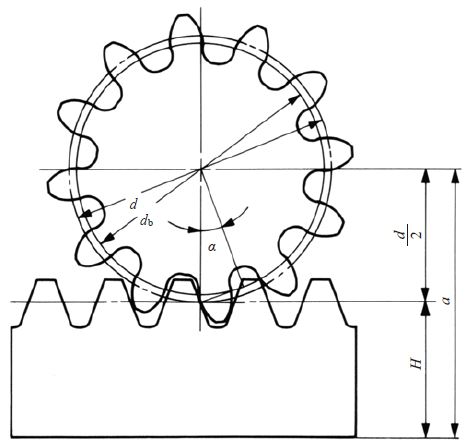

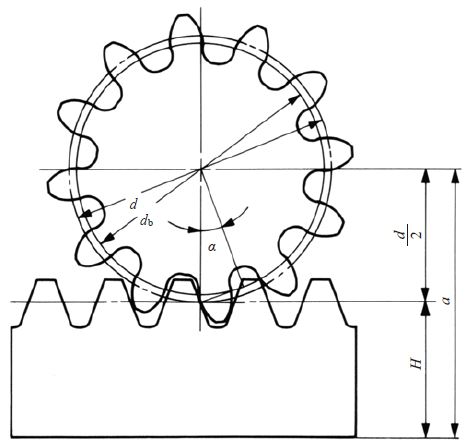

Figure 4.3 (1) shows the the meshing of standard gear and a rack. In this mesh, the reference circle of the gear touches the pitch line of the rack.

Figure 4.3 (2) shows a profile shifted spur gear, with positive correction xm, meshed with a rack. The spur gear has a larger pitch radius than standard, by the amount xm. Also, the pitch line of the rack has shifted outward by the amount xm.

Table 4.5 presents the calculation of a meshed profile shifted spur gear and rack. If the profile shift coefficient x1 is 0, then it is the case of a standard gear meshed with the rack.

Table 4.5 The calculations of dimensions of a profile shifted spur gear and a rack

One rotation of the spur gear will displace the rack l one circumferential length of the gear’s reference circle, per the formula :

The rack displacement, l, is not changed in any way by the profile shifting. Equation (4.2) remains applicable for any amount of profile shift.

Fig. 4.3 (1) The meshing of standard spur gear and rack

( α = 20°, z1 = 12, x1 = 0 )

Fig. 4.3 (2) The meshing of profile shifted spur gear and rack

( α = 20°, z1 = 12, x1 = + 0.6 )

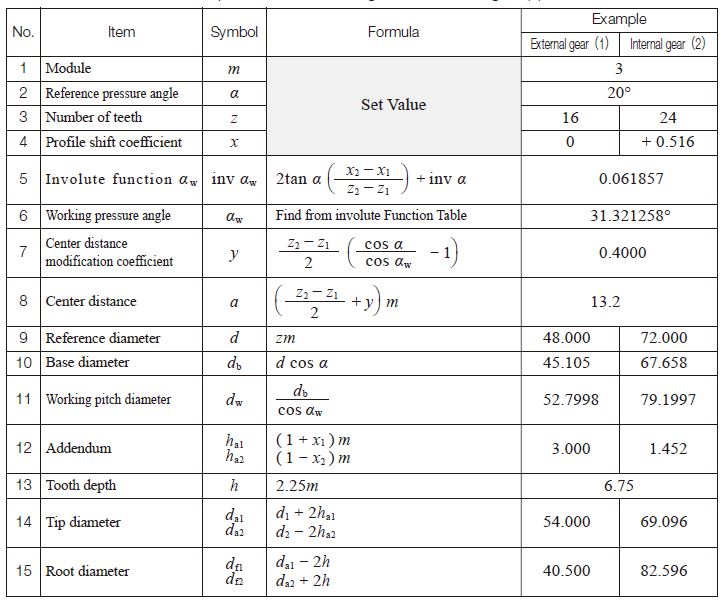

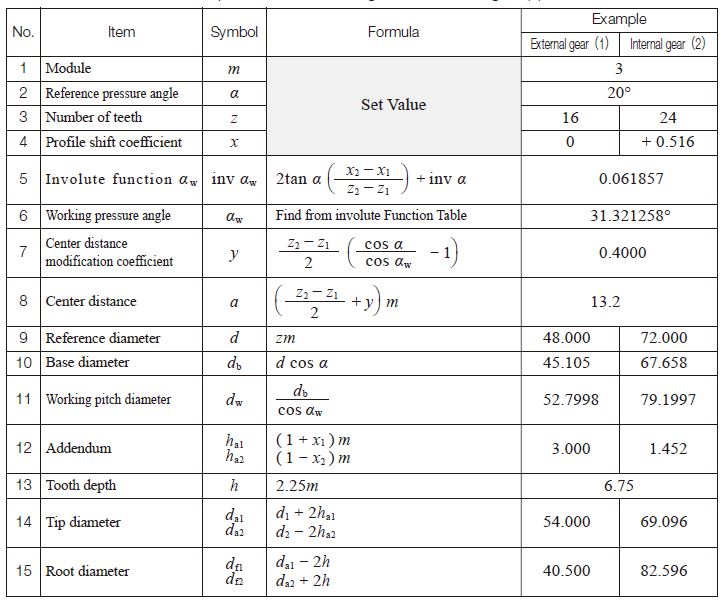

(1) Internal Gear Calculations

Figure 4.4 presents the mesh of an internal gear and external gear. Of vital importance is the working pitch diameters (dw) and working pressure angle (αw). They can be derived from center distance (a) and Equations (4.3).

Table 4.6 shows the calculation steps. It will become a standard gear calculation if x1 = x2 = 0.

Fig.4.4 The meshing of internal gear and external gear

( α = 20°, z1 = 16, z2 = 24, x1 = x2 = +0.5 )

Table 4.6 The calculations of a profile shifted internal gear and external gear (1)

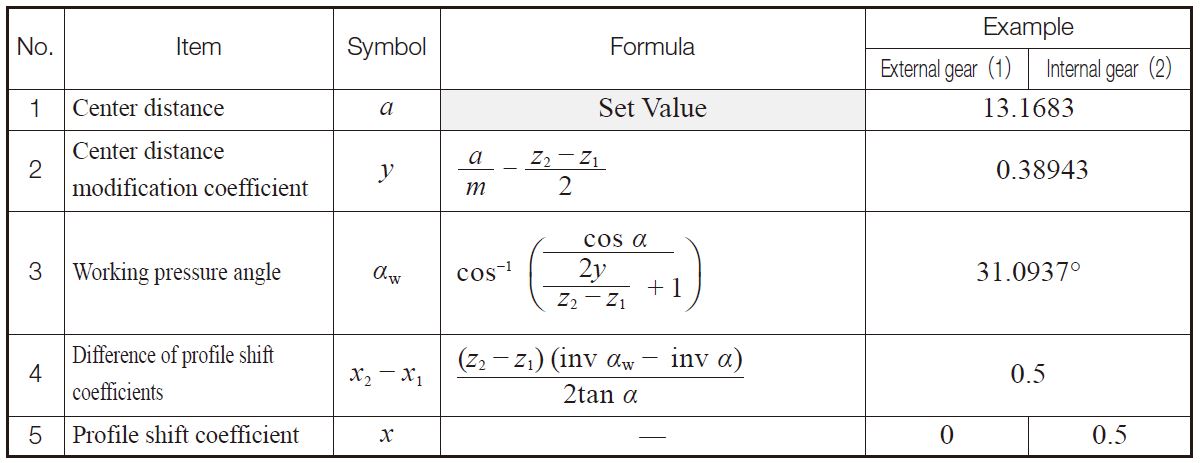

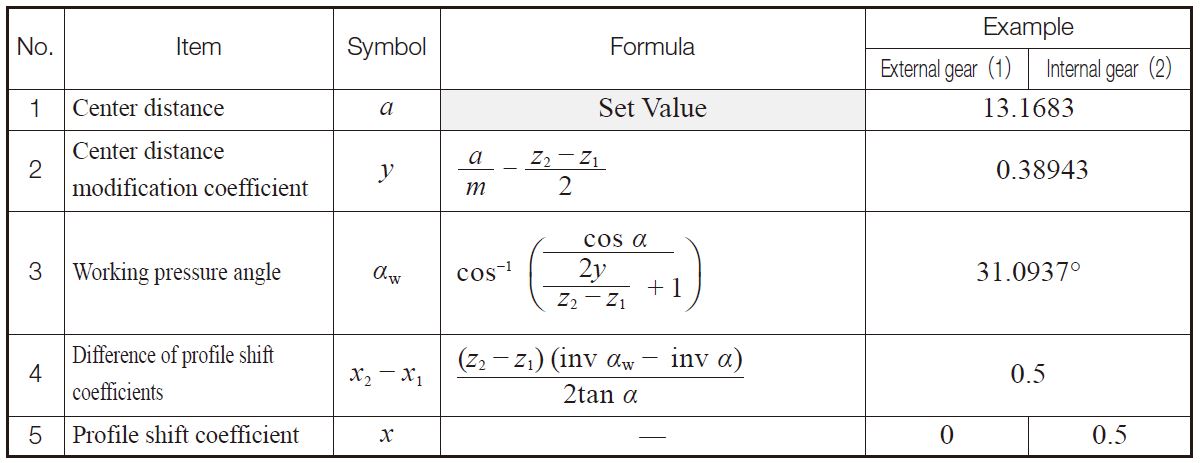

If the center distance (a) is given, x1 and x2 would be obtained from the inverse calculation from item 4 to item 8 of Table 4.6. These inverse formulas are in Table 4.7.

Table 4.7 The calculations of profile shifted internal gear and external gear (2)

Pinion cutters are often used in cutting internal gears and external gears. The actual value of tooth depth and root diameter, after cutting, will be slightly different from the calculation. That is because the cutter has a profile shift coefficient. In order to get a correct tooth profile, the profile shift coefficient of cutter should be taken into consideration.

(2) Interference In Internal Gears

Three different types of interference can occur with internal gears: (a) Involute Interference, (b) Trochoid Interference, and (c) Trimming Interference.

(a) Involute Interference

This occurs between the dedendum of the external gear and the addendum of the internal gear. It is prevalent when the number of teeth of the external gear is small. Involute interference can be avoided by the conditions cited below :

Where αa2 is the pressure angle at a tip of the internal gear tooth.

αw:working pressure angle

Equation (4.5) is true only if the tip diameter of the internal gear is bigger than the base circle :

For a standard internal gear, where α = 20° , Equation (4.7) is valid only if the number of teeth is z2 > 34.

(b) Trochoid Interference

This refers to an interference occurring at the addendum of the external gear and the dedendum of the internal gear during recess tooth action. It tends to happen when the difference between the numbers of teeth of the two gears is small. Equation (4.8) presents the condition for avoiding trochoidal interference.

Here

where αa1 is the pressure angle of the spur gear tooth tip:

In the meshing of an external gear and a standard internal gear α = 20° , trochoid interference is avoided if the difference of the number of teeth, z2 – z1, is larger than 9.

(c) Trimming Interference

This occurs in the radial direction in that it prevents pulling the gears apart. Thus, the mesh must be assembled by sliding the gears together with an axial motion. It tends to happen when the numbers of teeth of the two gears are very close. Equation (4.11) indicates how to prevent this type of interference.

Here

This type of interference can occur in the process of cutting an internal gear with a pinion cutter. Should that happen, there is danger of breaking the tooling. Table 4.8 (1) shows the limit for the pinion cutter to prevent trimming interference when cutting a standard internal gear, with pressure angle α0 = 20°, and no profile shift, i.e., x0 = 0.

Table 4.8 (1) The limit to prevent an internal gear from trimming interference

There will be an involute interference between the internal gear and the pinion cutter if the number of teeth of the pinion cutter ranges from 15 to 22 (z0 = 15 to 22). Table 4.8(2) shows the limit for a profile shifted pinion cutter to prevent trimming interference while cutting a standard internal gear. The correction (x0) is the magnitude of shift which was assumed to be: x0 = 0.0075z0 + 0.05.

Table 4.8 (2) The limit to prevent an internal gear from trimming interference

There will be an involute interference between the internal gear and the pinion cutter if the number of teeth of the pinion cutter ranges from 15 to 19 (z0 = 15 to 19).

Fig.4.5 Involute interference and trochoid interference

Fig.4.6 Trimming interference

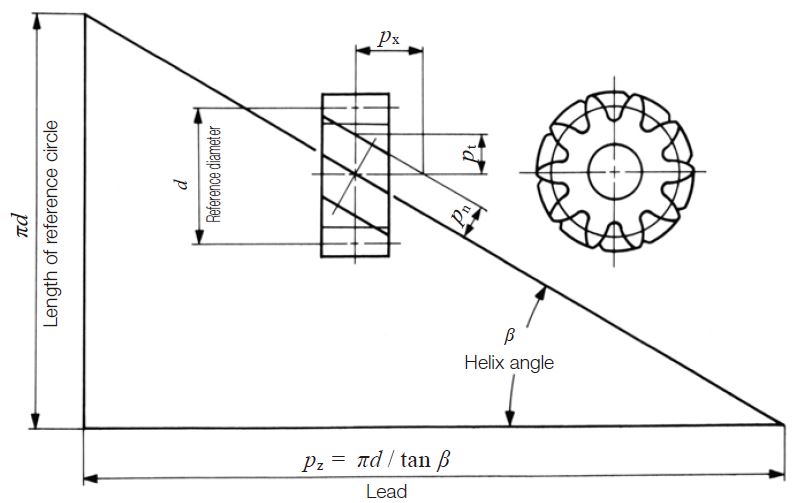

The tooth profile of a helical gear is an involute curve from an axial view, or in the plane perpendicular to the axis. The helical gear has two kinds of tooth profiles – one is based on a normal system, the other is based on a transverse system.

Pitch measured perpendicular to teeth is called normal pitch, pn.

And pn divided by π is then a normal module, mn.

The tooth profile of a helical gear with applied normal module,

mn, and normal pressure angle αn belongs to a normal system.

In the axial view, the pitch on the reference is called the transverse pitch, pt . And pt divided by π is the transverse module, mt.

These transverse module mt and transverse pressure angle αt at are the basic configuration of transverse system helical gear.

In the normal system, helical gears can be cut by the same gear hob if module mn and pressure angle at are constant, no matter what the value of helix angle β.

It is not that simple in the transverse system. The gear hob design must be altered in accordance with the changing of helix angle β, even when the module mt and the pressure angle at are the same.

Obviously, the manufacturing of helical gears is easier with the normal system than with the transverse system in the plane perpendicular to the axis.

When meshing helical gears, they must have the same helix angle but with opposite hands.

Fig.4.7 Fundamental relationship of a helical gear (Right-hand)

(1) Normal System Helical Gear

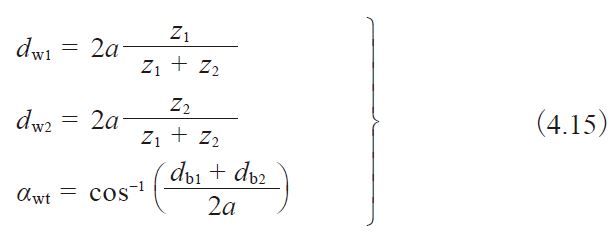

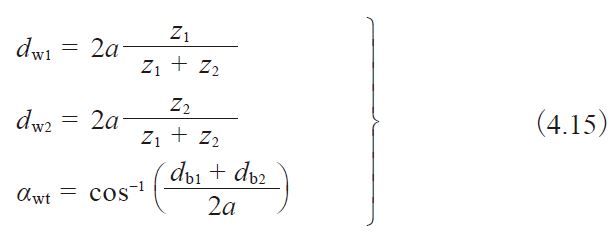

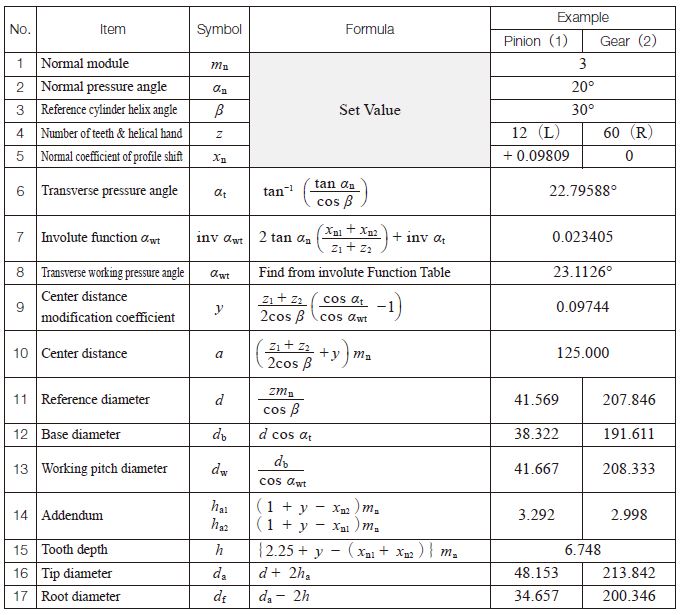

In the normal system, the calculation of a profile shifted helical gear, the working pitch diameter dw and transverse working pressure angle αwt is done per Equations (4.15). That is because meshing of the helical gears in the transverse plane is just like spur gears and the calculation is similar.

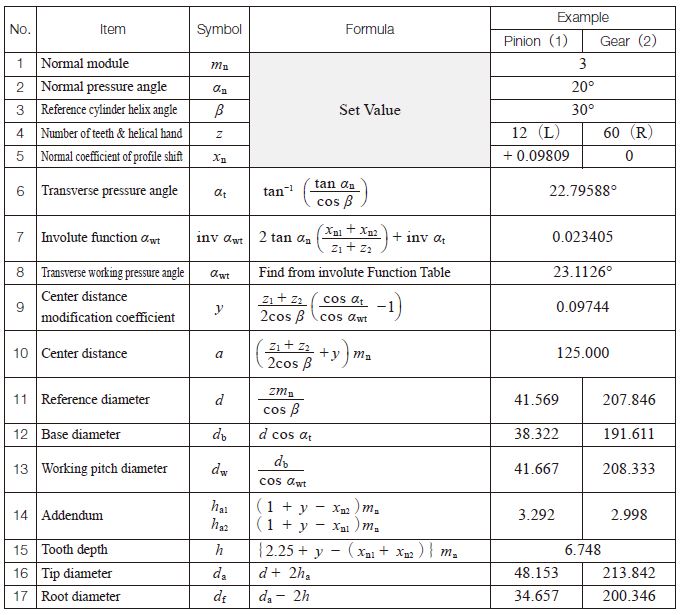

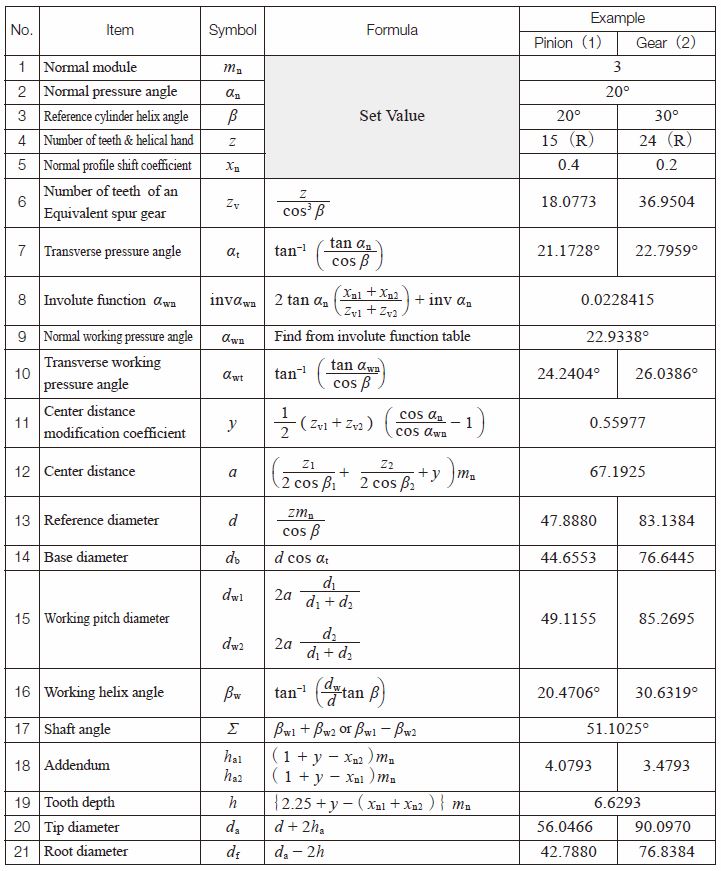

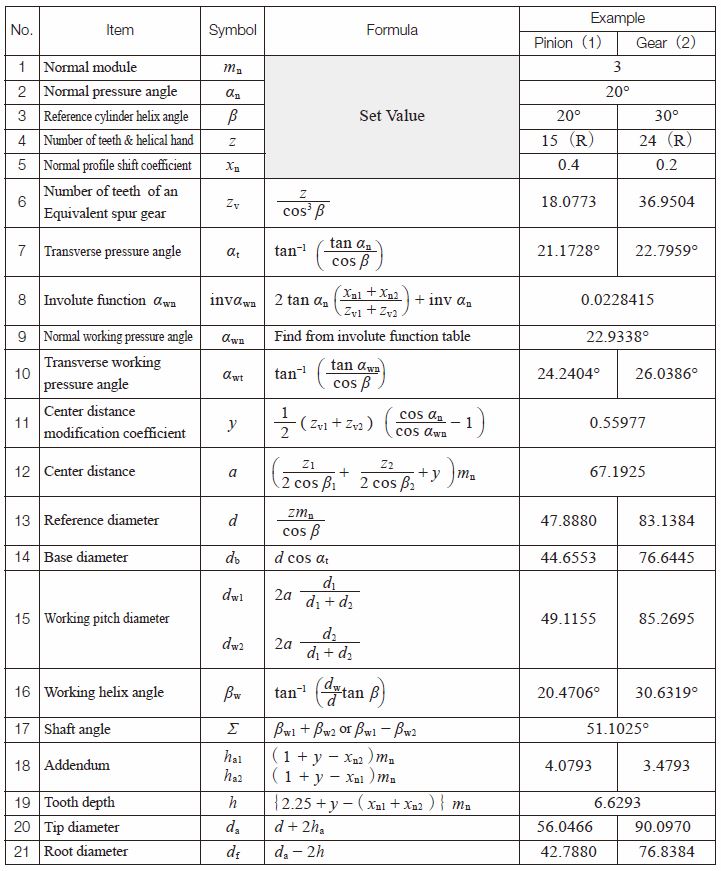

Table 4.9 shows the calculation of profile shifted helical gears in the normal system. If normal profile shift coefficients xn1, xn2 are zero, they become standard gears.

Table 4.9 The calculations of a profile shifted helical gear in the normal system (1)

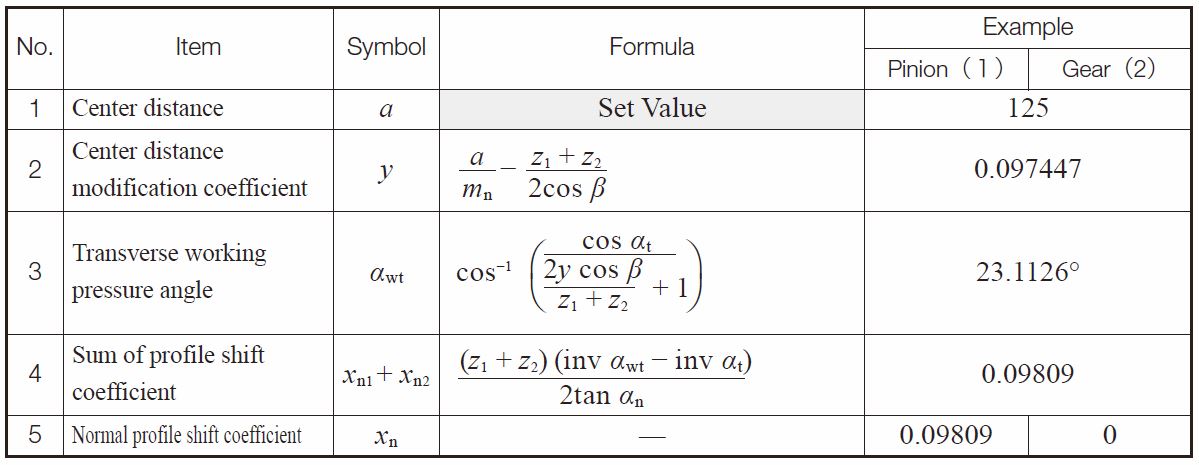

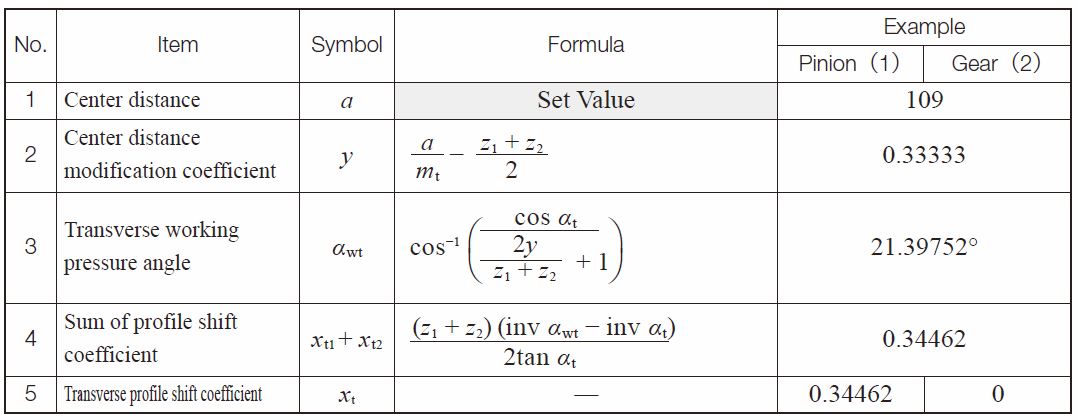

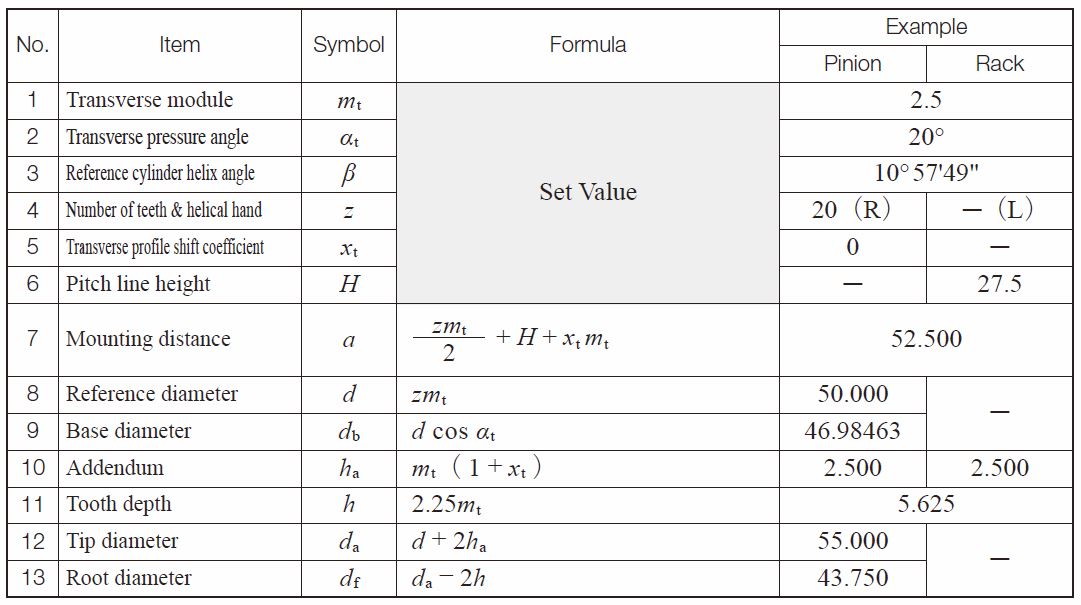

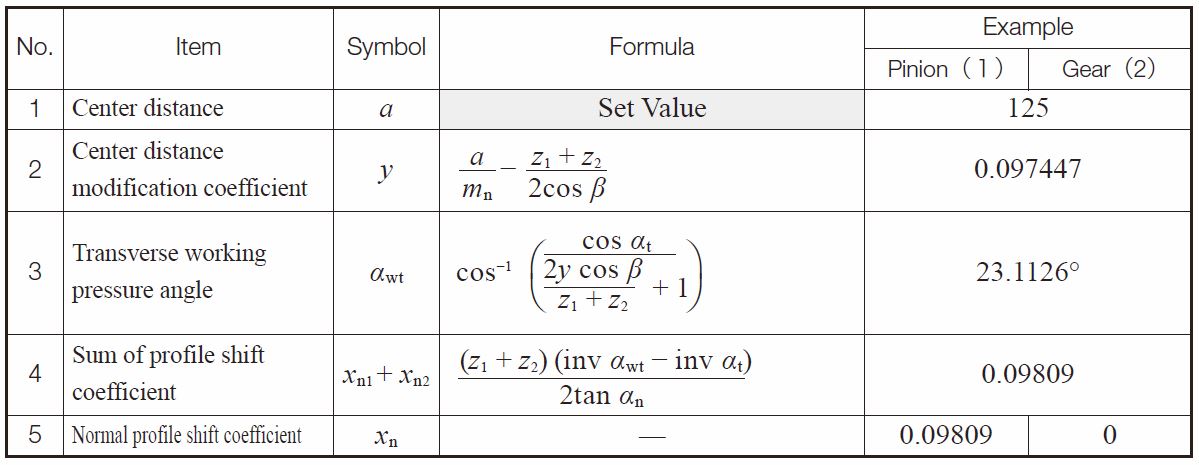

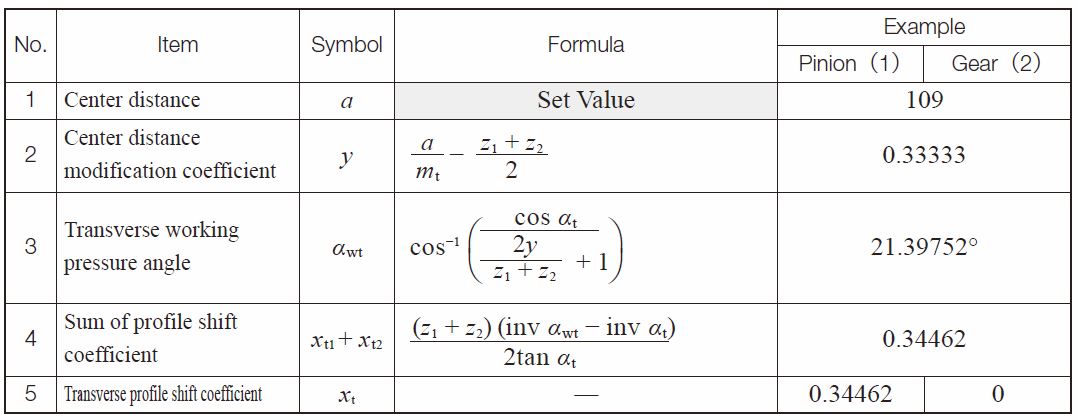

If center distance, α, is given, the normal profile shift coefficients xn1 and xn2 can be calculated from Table 4.10. These are the inverse equations from items 5 to 10 of Table 4.9.

Table 4.10 The calculations for a profile shifted helical gear in the normal system (2)

The transformation from a normal system to a transverse system is accomplished by the following equations :

(2) Transverse System Helical Gear

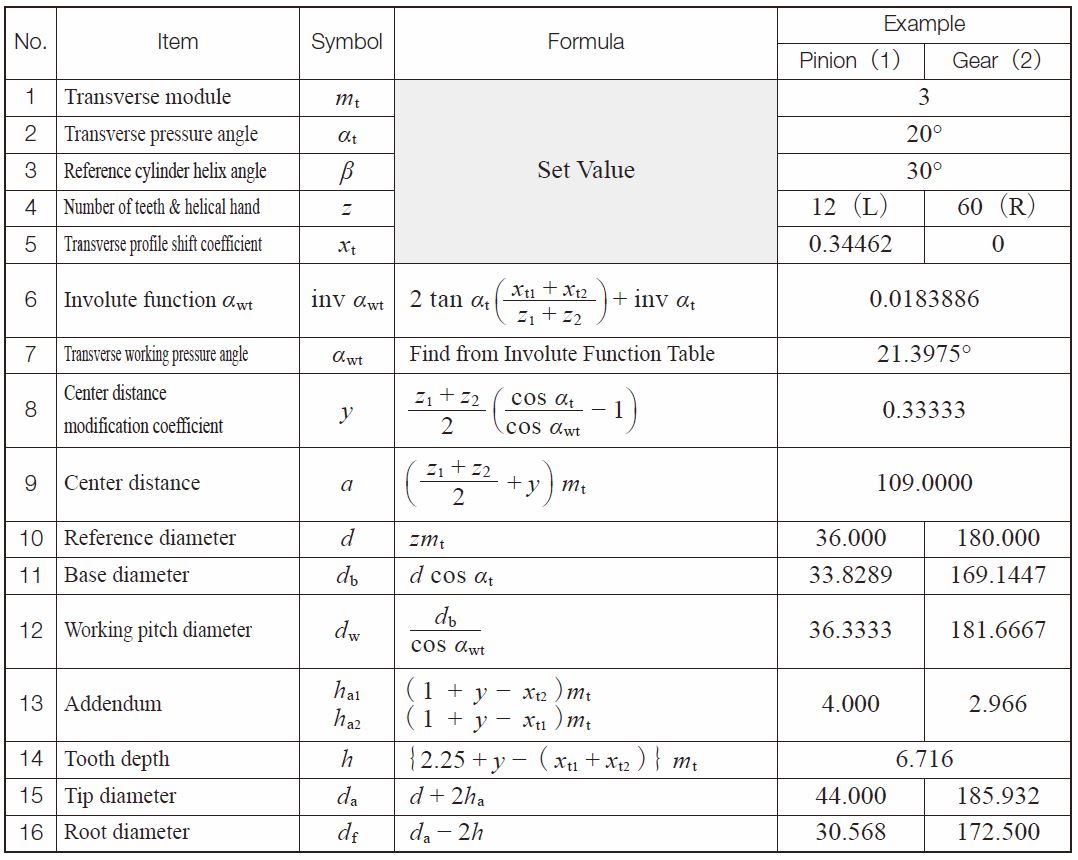

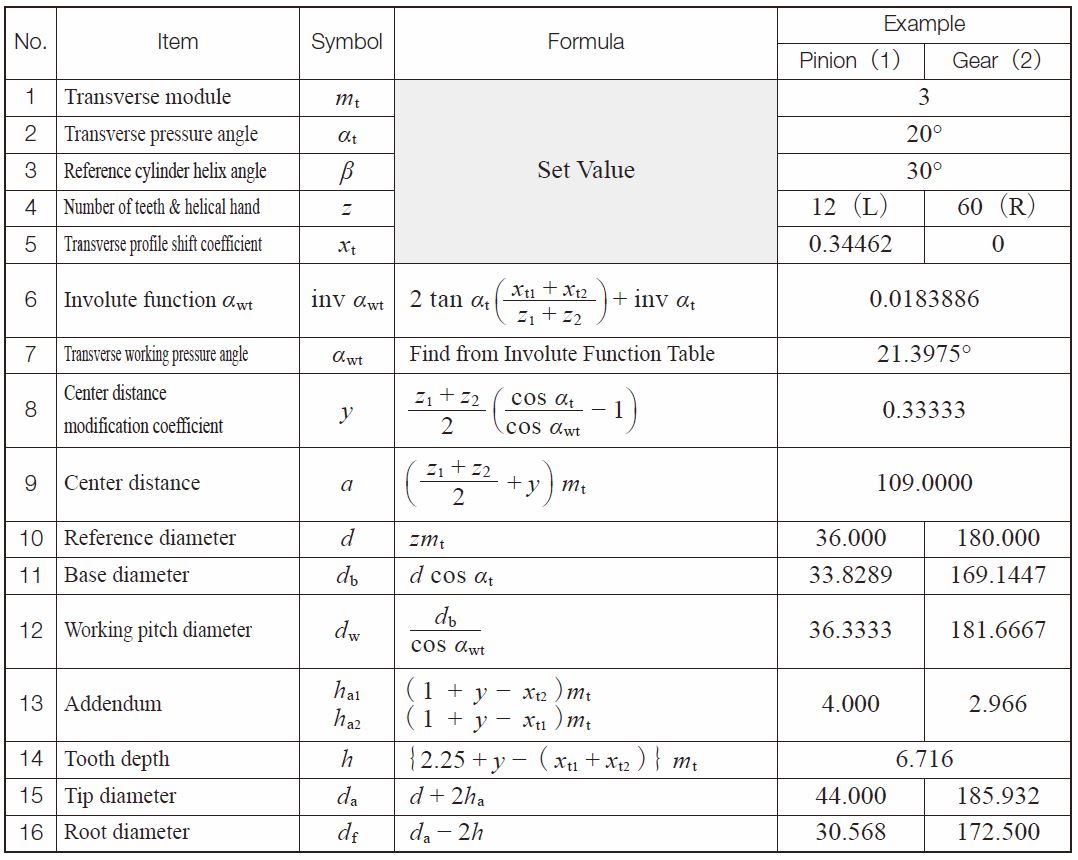

Table 4.11 shows the calculation of profile shifted helical gears in a transverse system. They become standard if xt1 = xt2 = 0.

Table 4.11 The calculations for a profile shifted helical gear in the transverse system (1)

Table 4.12 presents the inverse calculation of item 5 to 9 of Table 4.11.

Table 4.12 The calculations for a profile shifted helical gear in the transverse system (2)

The transformation from a transverse to a normal system is described by the following equations :

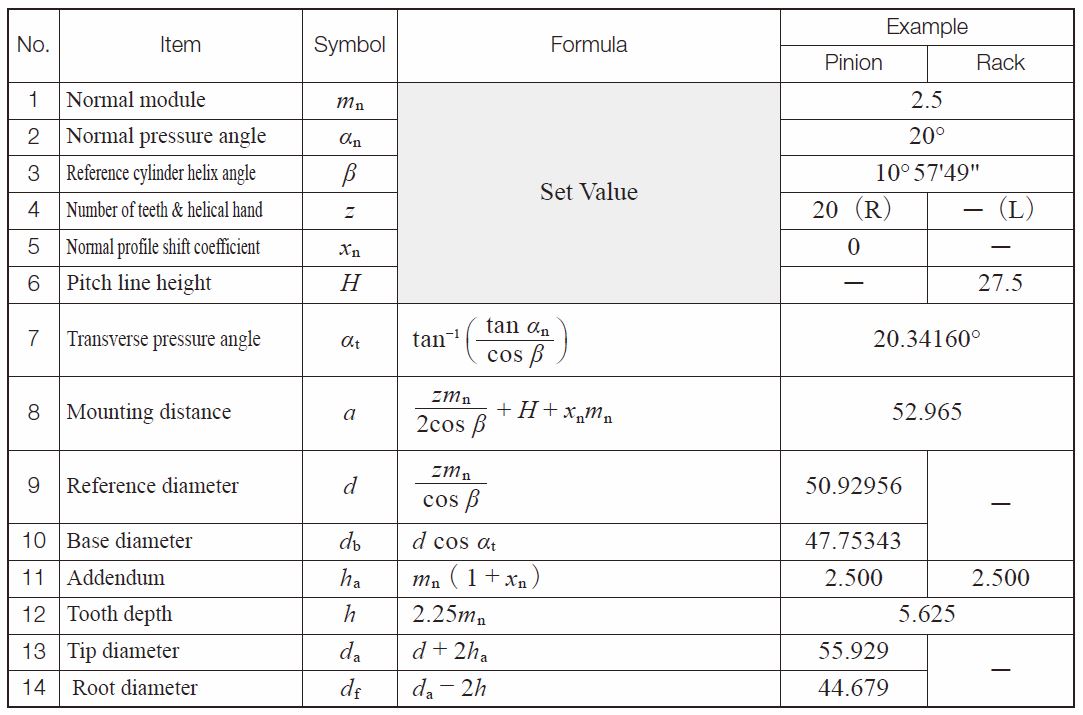

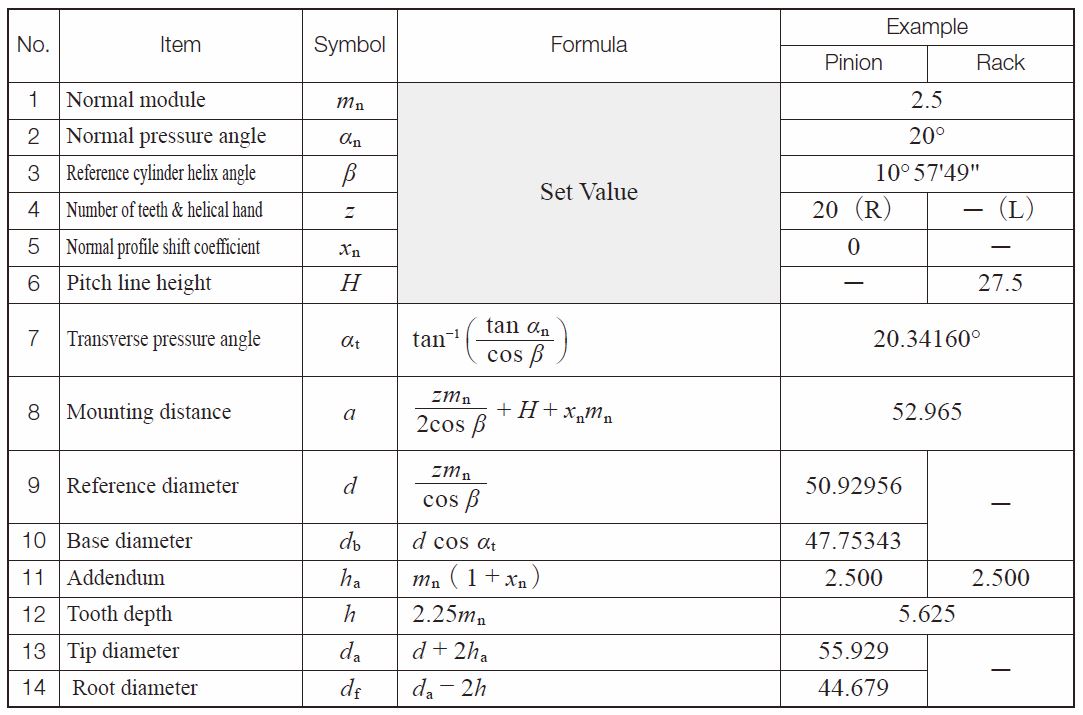

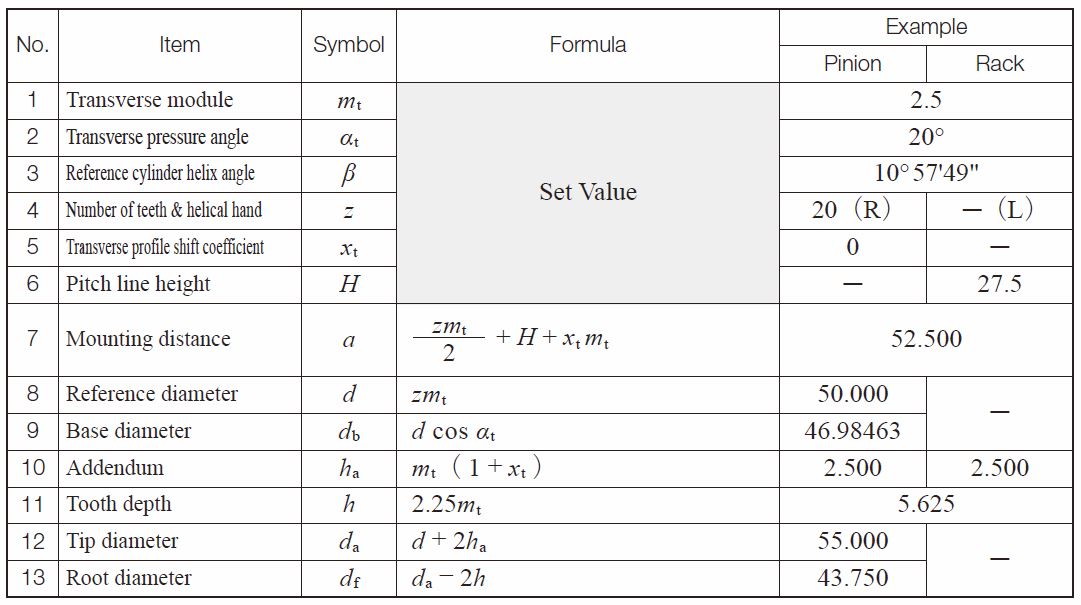

(3) Helical Rack

Viewed in the transverse plane, the meshing of a helical rack and gear is the same as a spur gear and rack. Table 4.13 presents the calculation examples for a mated helical rack with normal module and normal pressure angle. Similarily, Table 4.14 presents examples for a helical rack in the transverse system (i.e., perpendicular to gear axis).

Table 4.13 The calculations for a helical rack in the normal system

The formulas of a standard helical rack are similar to those of Table 4.14 with only the normal profile shift coefficient xn = 0.

To mesh a helical gear to a helical rack, they must have the same helix angle but with opposite hands.

The displacement of the helical rack, l, for one rotation of the mating gear is the product of the transverse pitch and number of teeth.

According to the equations of Table 4.13, let transverse pitch pt = 8 mm and displacement l = 160 mm. The transverse pitch and the displacement could be resolved into integers, if the helix angle were chosen properly.

Table 4.14 The calculations for a helical rack in the transverse system

In the meshing of transverse system helical rack and helical gear, the movement, l, for one turn of the helical gear is the transverse pitch multiplied by the number of teeth.

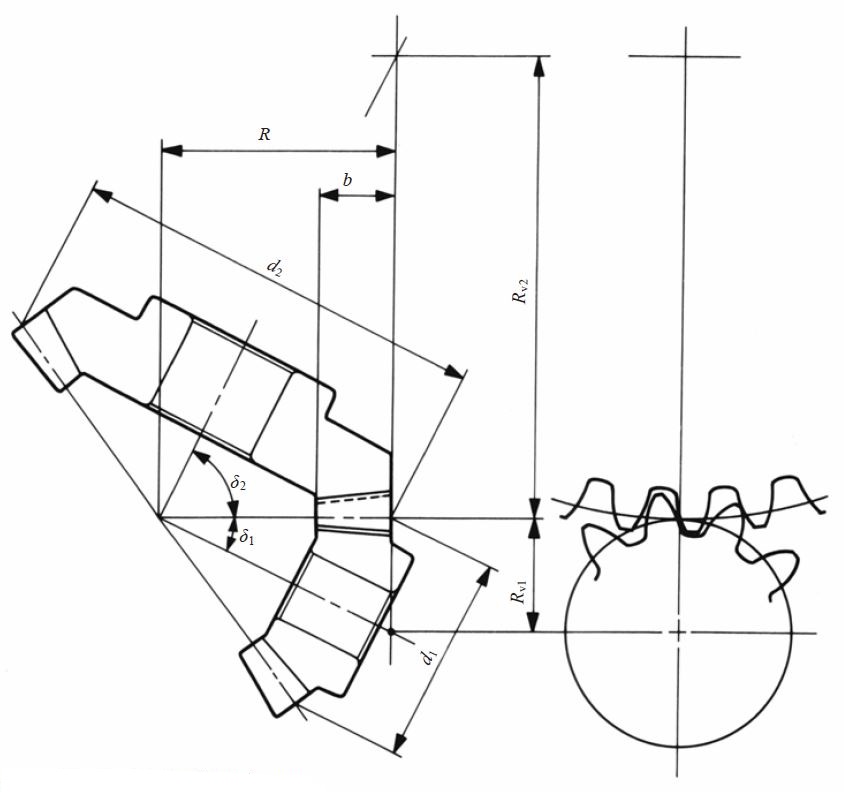

Fig. 4.8 The reference cone angle of bevel gear

Generally, a shaft angle Σ = 90° is most used. Other angles (Figure 4.8) are sometimes used. Then, it is called “bevel gear in nonright angle drive”. The 90° case is called “bevel gear in right angle drive”. When Σ = 90°, Equation (4.20) becomes :

Miter gears are bevel gears with Σ = 90° and z1 = z2. Their transmission ratio z2 / z1 = 1.

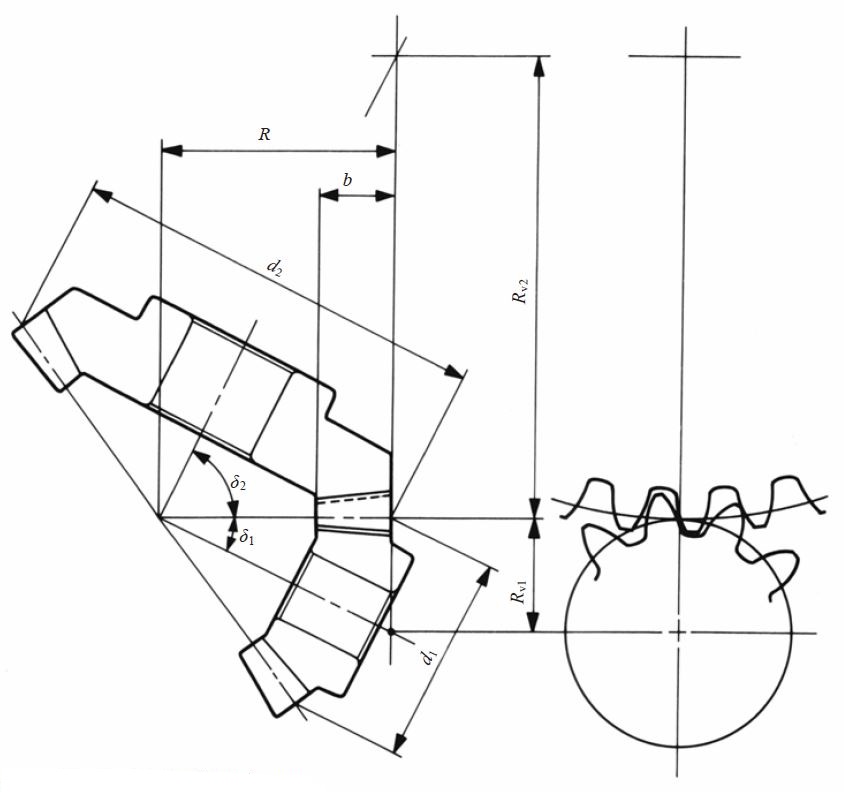

Figure 4.9 depicts the meshing of bevel gears. The meshing must be considered in pairs. It is because the reference cone angles δ1 and δ2 are restricted by the gear ratio z2 / z1. In the facial view, which is normal to the contact line of pitch cones, the meshing of bevel gears appears to be similar to the meshing of spur gears.

Fig. 4.9 The meshing of bevel gears

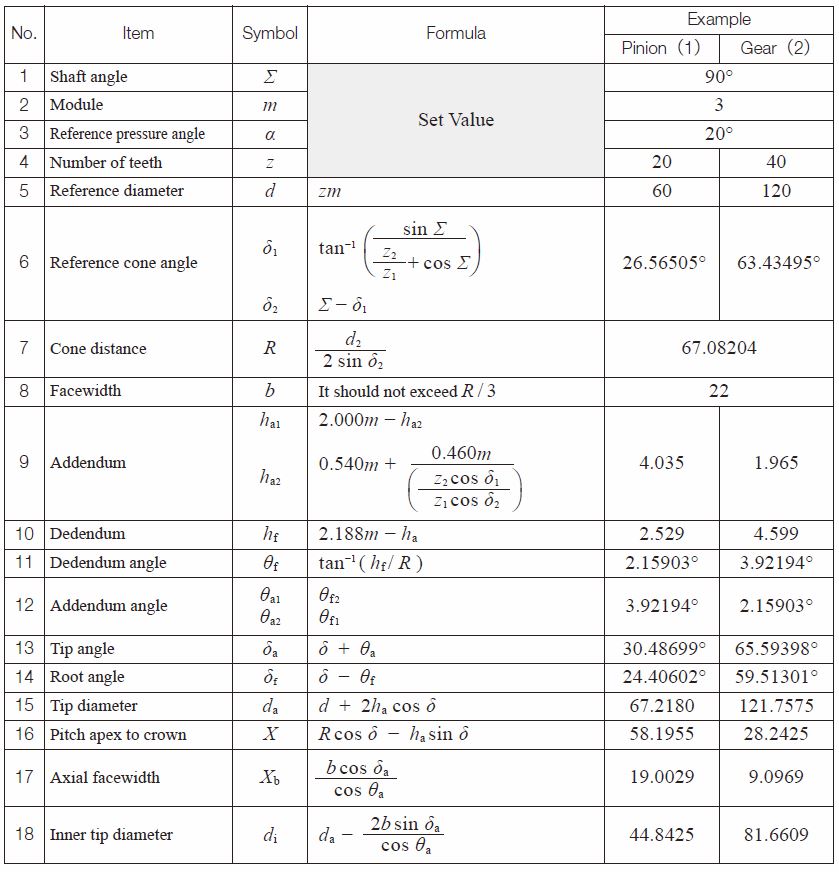

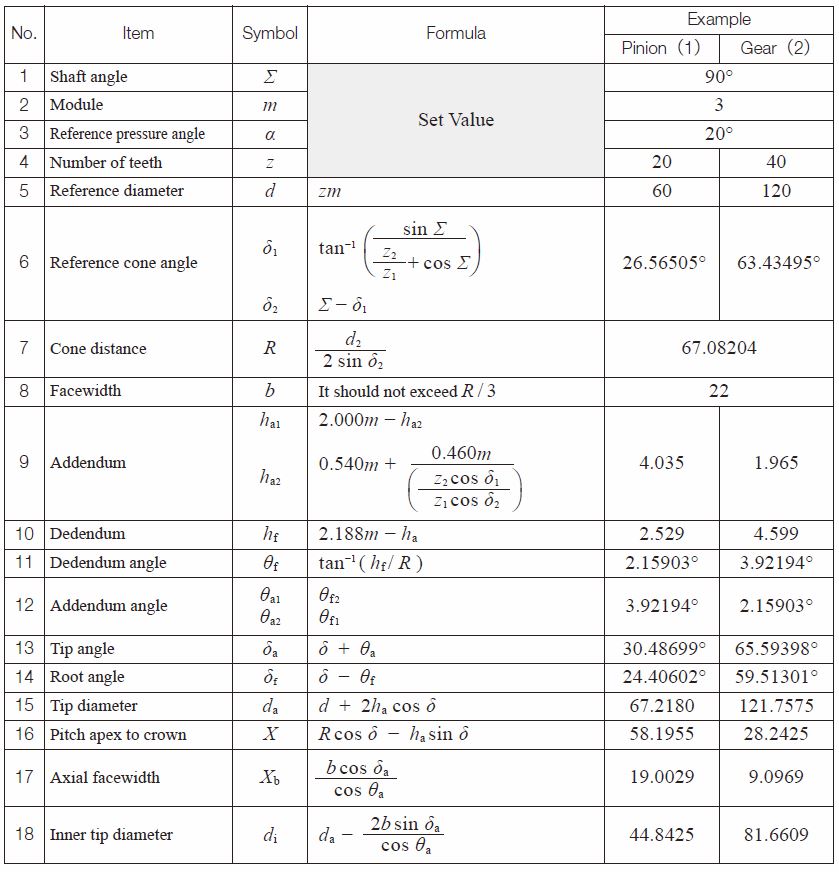

(1) Gleason Straight Bevel Gears

A straight bevel gear is a simple form of bevel gear having straight teeth which, if extended inward, would come together at the intersection of the shaft axes. Straight bevel gears can be grouped into the Gleason type and the standard type.

In this section, we discuss the Gleason straight bevel gear. The Gleason Company defines the tooth profile as: tooth depth h = 2.188m; tip and root clearance c = 0.188m; and working depth hw = 2.000m.

The characteristics are :

** Design specified profile shifted gears

In the Gleason system, the pinion is positive shifted and the gear is negative shifted. The reason is to distribute the proper strength between the two gears. Miter gears, thus, do not need any shift.

** The tip and root clearance is designed to be parallel

The face cone of the blank is turned parallel to the root cone of the mate in order to eliminate possible fillet interference at the small end of the teeth.

Fig. 4.10 Dimensions and angles of bevel gears

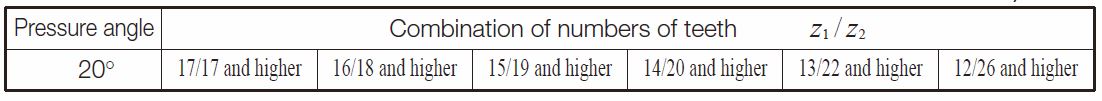

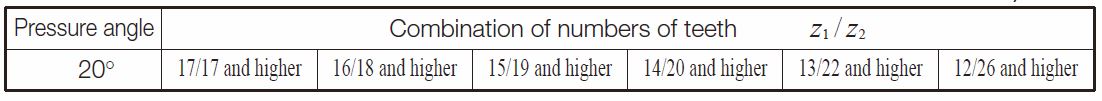

Table 4.15 shows the minimum number of the teeth to prevent undercut in the Gleason system at the shaft angle Σ = 90.°

Table 4.15 The minimum numbers of teeth to prevent undercut

Table 4.16 presents equations for designing straight bevel gears in the Gleason system. The meanings of the dimensions and angles are shown in Figure 4.10 above. All the equations in Table 4.16 can also be applied to bevel gears with any shaft angle.

The straight bevel gear with crowning in the Gleason system is called a Coniflex gear. It is manufactured by a special Gleason “Coniflex” machine. It can successfully eliminate poor tooth contact due to improper mounting and assembly.

Tale 4.16 The calculations of straight bevel gears of the Gleason system

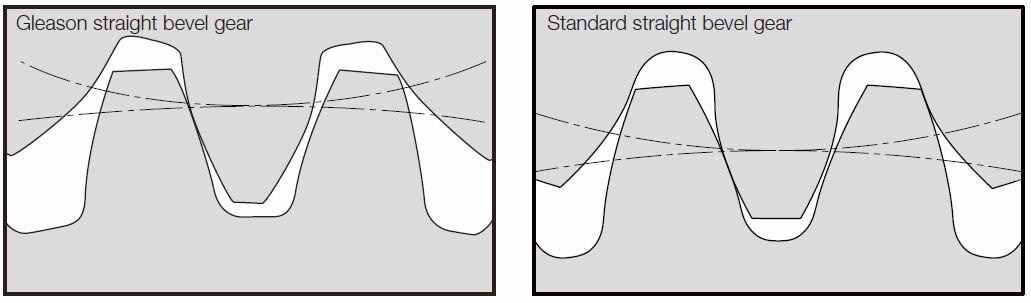

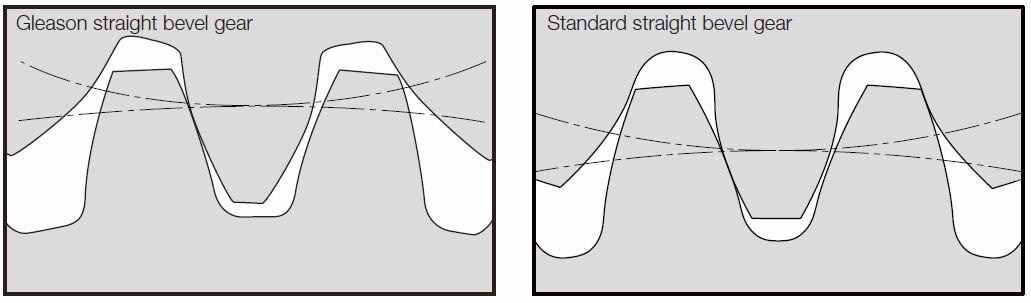

The first characteristic of a Gleason Straight Bevel Gear that it is a profile shifted tooth. From Figure 4.11, we can see the tooth profile of Gleason Straight Bevel Gear and the same of Standard Straight Bevel Gear.

Fig. 4.11 The tooth profile of straight bevel gears

(2) Standard Straight Bevel Gears

A bevel gear with no profile shifted tooth is a standard straight bevel gear. The are also referred to as Klingelnberg bevel gears. The applicable equations are in Table 4.17.

Table 4.17 The calculations for a standard straight bevel gears

These equations can also be applied to bevel gear sets with other than 90° shaft angles.

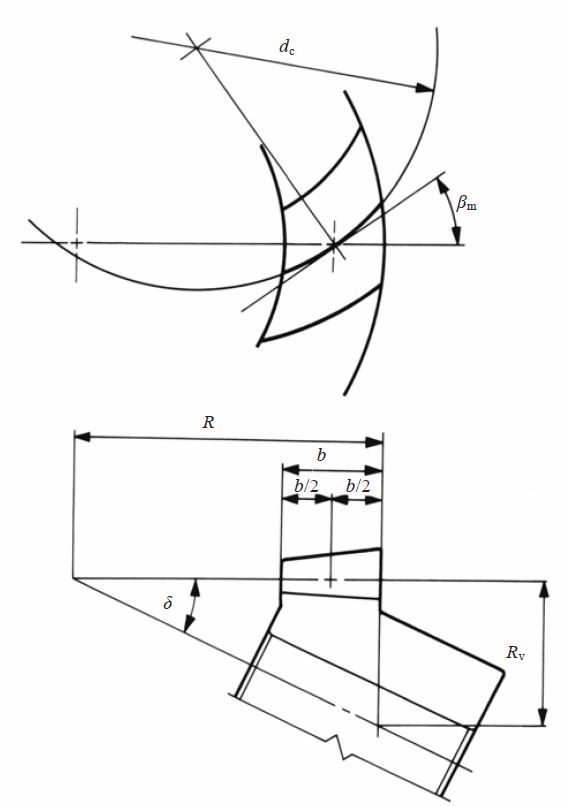

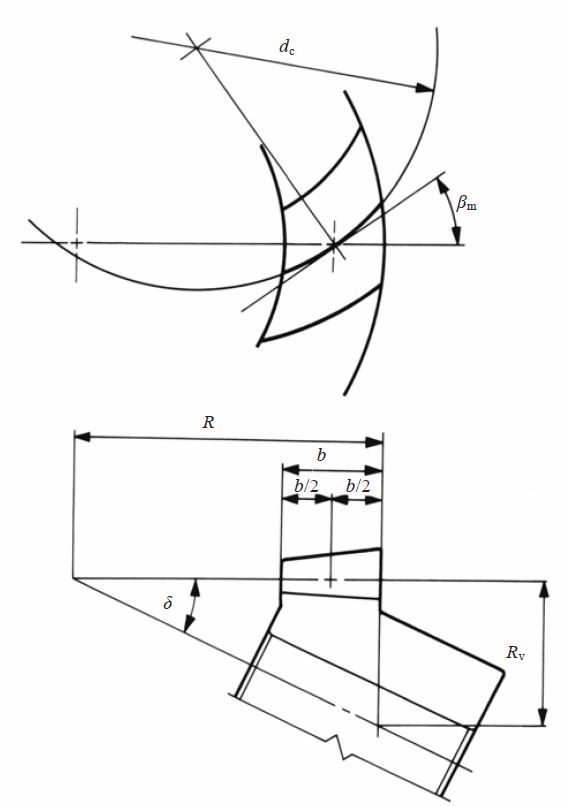

(3) Gleason Spiral Bevel Gears

A spiral bevel gear is one with a spiral tooth flank as in Figure 4.12. The spiral is generally consistent with the curve of a cutter with the diameter dc. The spiral angle β is the angle between a generatrix element of the pitch cone and the tooth flank. The spiral angle just at the tooth flank center is called the mean spiral angle βm. In practice, the term spiral angle refers to the mean spiral angle.

Fig.4.12 Spiral Bevel Gear (Left-hand)

All equations in Table 4.20 are specific to the manufacturing method of Spread Blade or of Single Side from Gleason. If a gear is not cut per the Gleason system, the equations will be different from these.

The tooth profile of a Gleason spiral bevel gear shown here has the tooth depth h = 1.888m; tip and root clearance c = 0.188m; and working depth hw = 1.700m. These Gleason spiral bevel gears belong to a stub gear system. This is applicable to gears with modules m > 2.1.

Table 4.18 shows the minimum number of teeth to avoid undercut in the Gleason system with shaft angle Σ = 90° and pressure angle αn = 20°.

Table 4.18 The minimum numbers of teeth to prevent undercut β=35°

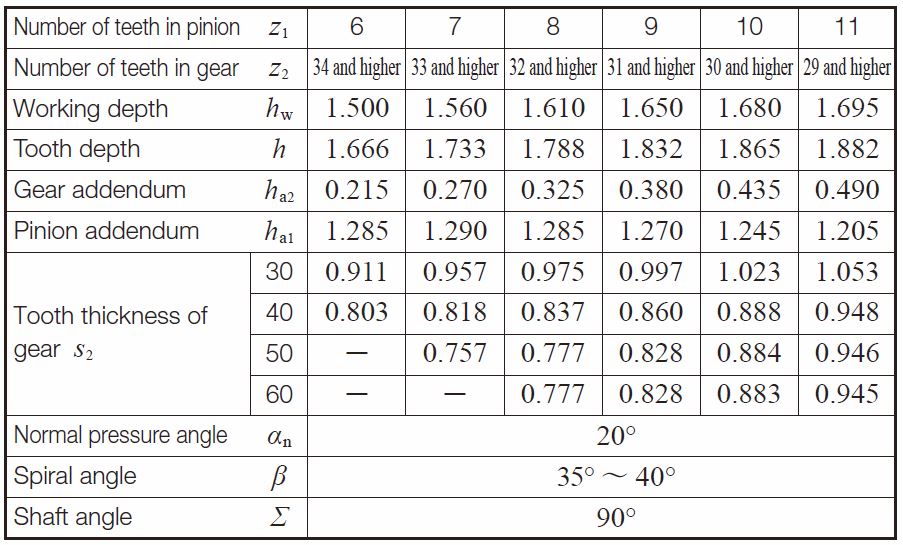

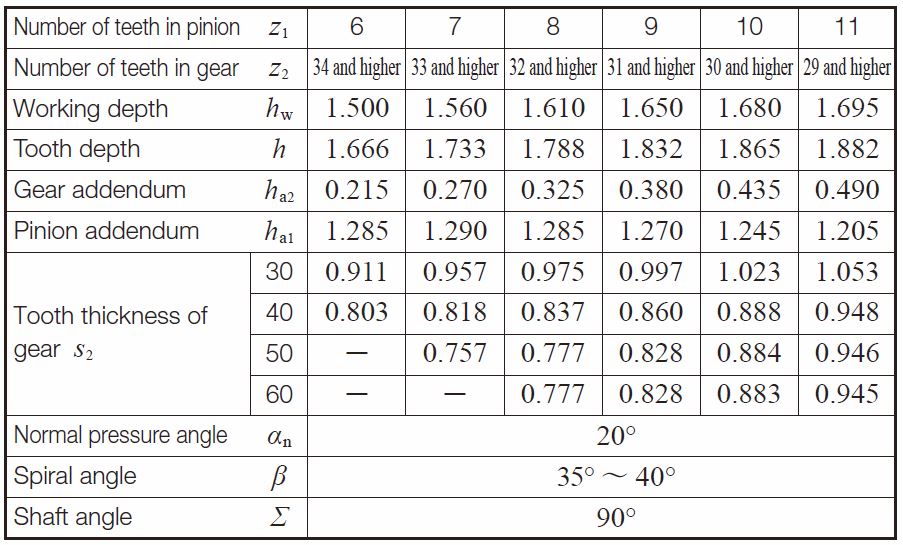

If the number of teeth is less than 12, Table 4.19 is used to determine the gear sizes.

Table 4.19 Dimentions for pinions with number of teeth less than 12

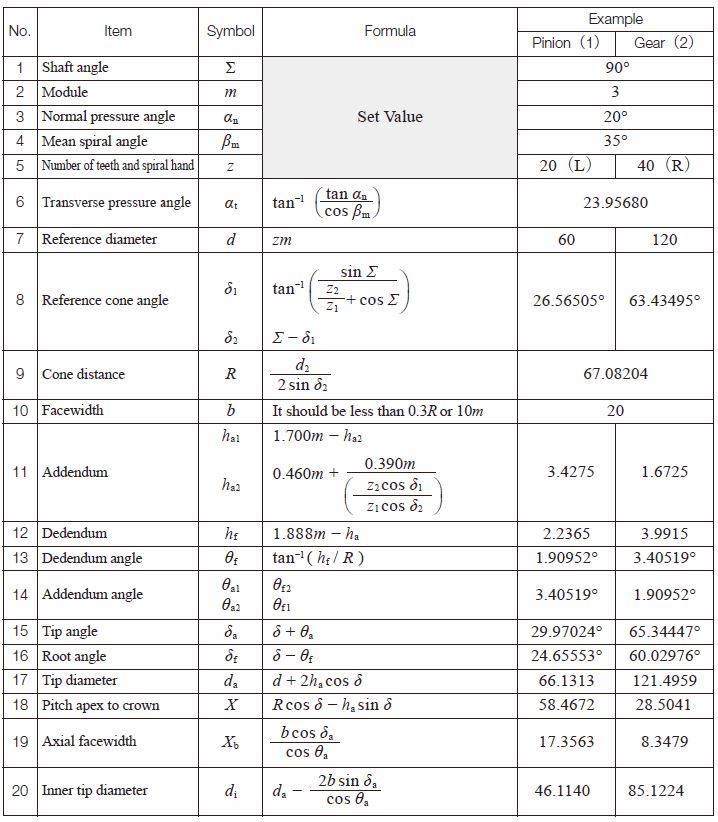

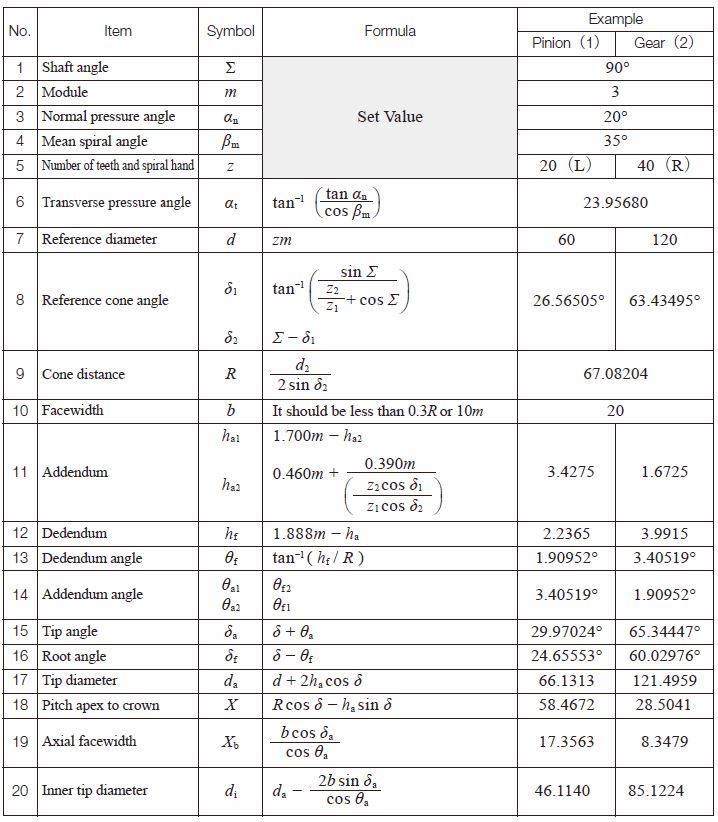

Table 4.20 shows the calculations for spiral bevel gears in the Gleason system

Table 4.20 The calculations for spiral bevel gears in the Gleason system

All equations in Table 4.20 are also applicable to Gleason bevel gears with any shaft angle. A spiral bevel gear set requires matching of hands; left-hand and right-hand as a pair.

(4) Gleason Zerol Bevel Gears

When the spiral angle bm = 0, the bevel gear is called a Zerol bevel gear. The calculation equations of Table 4.16 for Gleason straight bevel gears are applicable. They also should take care again of the rule of hands; left and right of a pair must be matched. Figure 4.13 is a left-hand Zerol bevel gear.

Fig. 4.13 Left-hand zerol bevel gear

Fig.4.14 Screw gears of nonparallel and nonintersecting axes

Let a pair of screw gears have the shaft angle Σ and helix angles β1 and β2 :

If the screw gears were profile shifted, the meshing would become a little more complex. Let βw1, βw2 represent the working pitch cylinder ;

Table 4.21 presents equations for a profile shifted screw gear pair. When the normal profile shift coefficients xn1 = xn2 = 0, the equations and calculations are the same as for standard gears.

Table 4.21 The equations for a screw gear pair on nonparallel and Nonintersecting axes in the normal system

Standard screw gears have relations as follows:

dw1 = d1

dw2 = d2

βw1 = β1

βw2 = β2

(4.24)

There are four worm tooth profiles in JIS B 1723-1977, as defined below.

Type I : The tooth profile is trapezoidal on the axial plane.

Type II : The tooth profile is trapezoid on the plane normal to the space.

Type III : The tooth profile which is obtained by inclining the axis of the milling or grinding, of which cutter shape is trapezoidal on the cutter axis, by the lead angle to the worm axis.

Type IV : The tooth profile is of involute curve on the plane of rotation.

KHK stock worm gear products are all Type III. Worm profiles (Fig 4.15). The cutting tool used to process worm gears is called a single-cutter that has a single-edged blade. The cutting of worm gears is done with worm cutting machine. Because the worm mesh couples nonparallel and nonintersecting axes, the axial plane of worm does not correspond with the axial plane of worm wheel. The axial plane of worm corresponds with the transverse plane of worm wheel. The transverse plane of worm corresponds with the axial plane of worm wheel. The common plane of the worm and worm wheel is the normal plane. Using the normal module, mn, is most popular. Then, an ordinary hob can be used to cut the worm wheel.

Fig. 4.15 Cutting – Grinding for Type III Worm

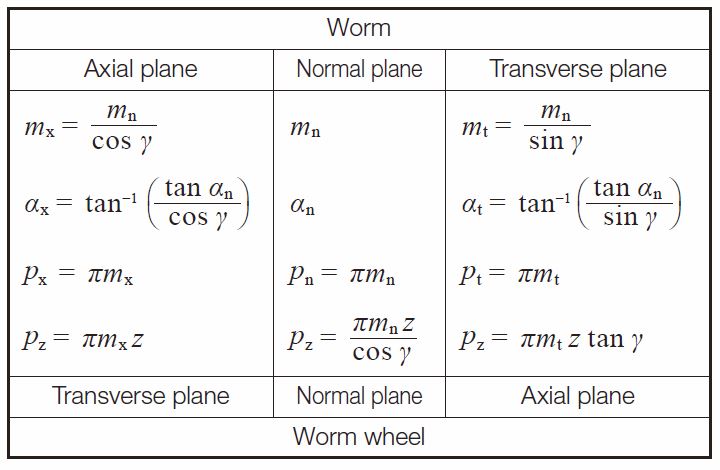

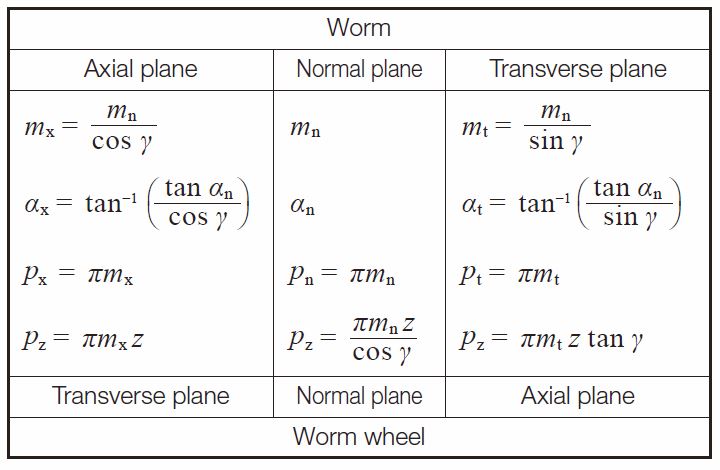

Table 4.22 presents the relationships among worm and worm wheel with regard to axial plane, transverse plane, normal plane, module, pressure angle, pitch and lead.

Fig. 4.16 Cylindrical worm (Right-hand)

Table 4.22 The relations of cross sections of worm gear pairs

Reference to Figure 4.16 can help the understanding of the relationships in Table 4.22. They are similar to the relations in Formulas (4.16) and (4.17) in that the helix angle β be substituted by (90 deg – γ). We can consider that a worm with lead angle γ is almost the same as a helical gear with helix angle (90 deg – γ).

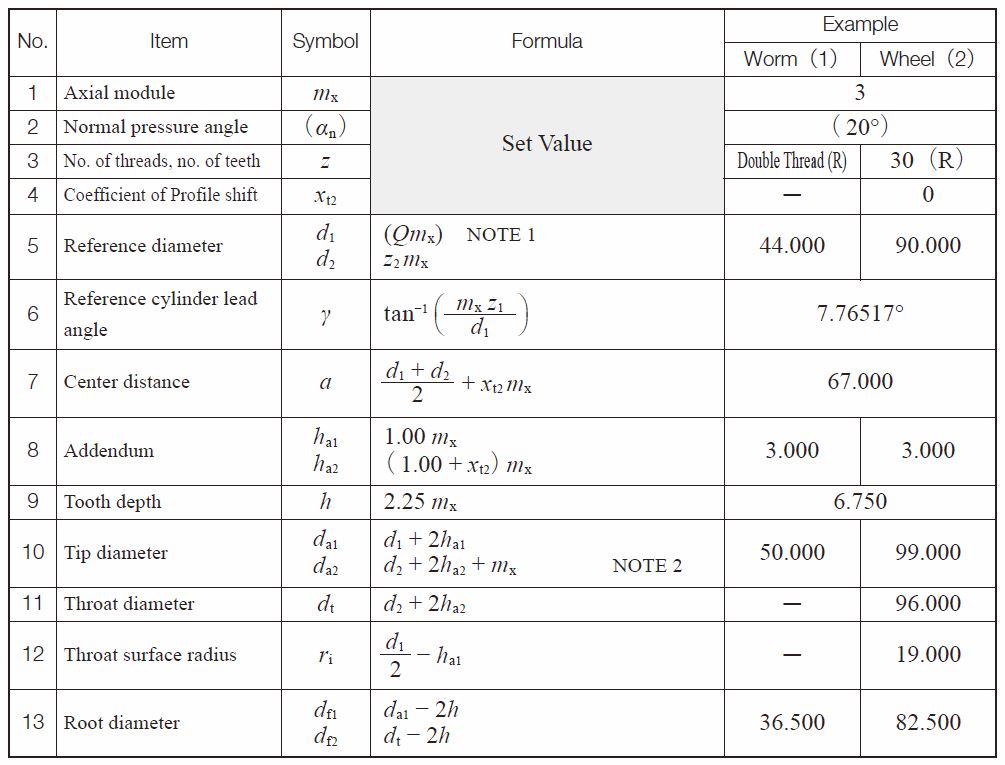

(1) Axial Module Worm Gear Pair

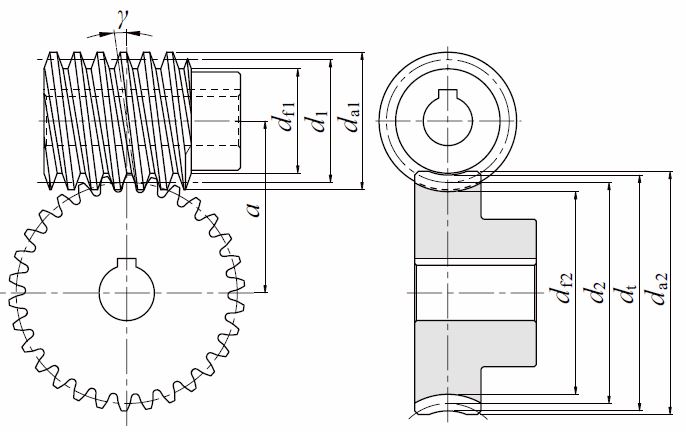

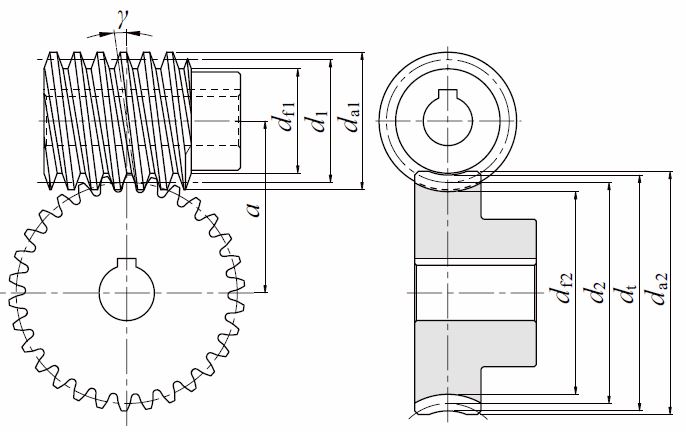

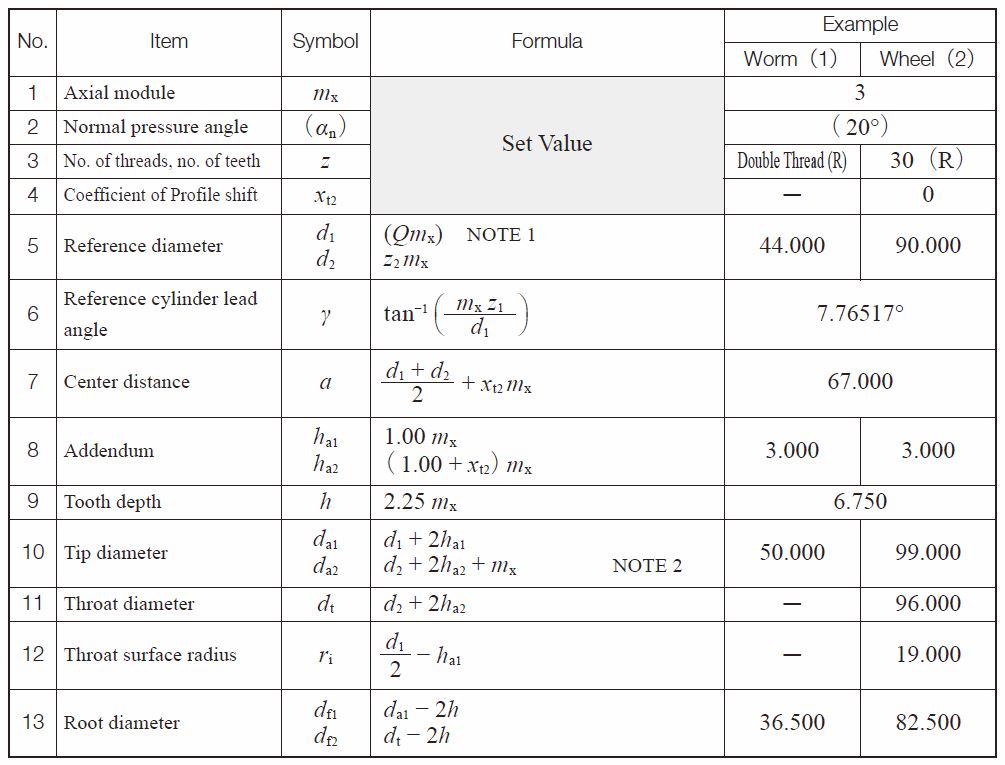

Table 4.23 presents the equations, for dimensions shown in Figure 4.16, for worm gears with axial module, mx, and normal pressure angle αn = 20°.

Fig. 4.17 Dimentions of cylindrical worm gear pair

Table 4.23 The calculations for an axial module system worm gear pair

NOTE 1.

Diameter factor, Q, means reference diameter of worm, d1, over axial module, mx.

Q = d1 / mx

NOTE 2.

There are several calculation methods of worm wheel tip diameter da2 besides those in Table 4.25.

NOTE 3.

The facewidth of worm, b1, would be sufficient if: b1 = πmx (4.5 + 0.02z2)

NOTE 4.

Effective facewidth of worm wheel bw =

So the actual facewidth of b2 ≧ bw + 1.5mx would be enough.

(2) Normal Module System Worm Gear Pair

The equations for normal module system worm gears are based on a normal module, mn, and normal pressure angle, αn = 20°. See Table 4.24.

Table 4.24 The calculations for a normal module system worm gear pair

NOTE : All notes are the same as those of Table 4.23.

(3) Crowning of the Tooth

Crowning is critically important to worm gears. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of an oil film, which enhances the lubrication effect of the mesh. This can favorably impact endurance and transmission efficiency of the worm mesh. There are four methods of crowning worm gear pair :

(a) Cut Worm Wheel with a Hob Cutter of Greater Reference Diameter than the Worm.

A crownless worm wheel results when it is made by using a hob that has an identical pitch diameter as that of the worm. This crownless worm wheel is very difficult to assemble correctly. Proper tooth contact and a complete oil film are usually not possible.

However, it is relatively easy to obtain a crowned worm wheel by cutting it with a hob whose reference diameter is slightly larger than that of the worm.

This is shown in Figure 4.18. This creates teeth contact in the center region with space for oil film formation.

Fig.4.18 The method of using a greater diameter hob

(b) Recut With Hob Center Position Adjustment.

The first step is to cut the worm wheel at standard center distance. This results in no crowning. Then the worm wheel is finished with the same hob by recutting with the hob axis shifted parallel to the worm wheel axis by ±Δh. This results in a crowning effect, shown in Figure 4.19.

Fig.4.19 Offsetting up or down

(c) Hob Axis Inclining Δθ From Standard Position.

In standard cutting, the hob axis is oriented at the proper angle to the worm wheel axis. After that, the hob axis is shifted slightly left and then right, Δθ, in a plane parallel to the worm wheel axis, to cut a crown effect on the worm wheel tooth.

This is shown in Figure 4.20. Only method (a) is popular. Methods (b) and (c) are seldom used.

Fig. 4.20 Inclining right or left

(d) Use a Worm with a Larger Pressure Angle than the Worm Wheel.

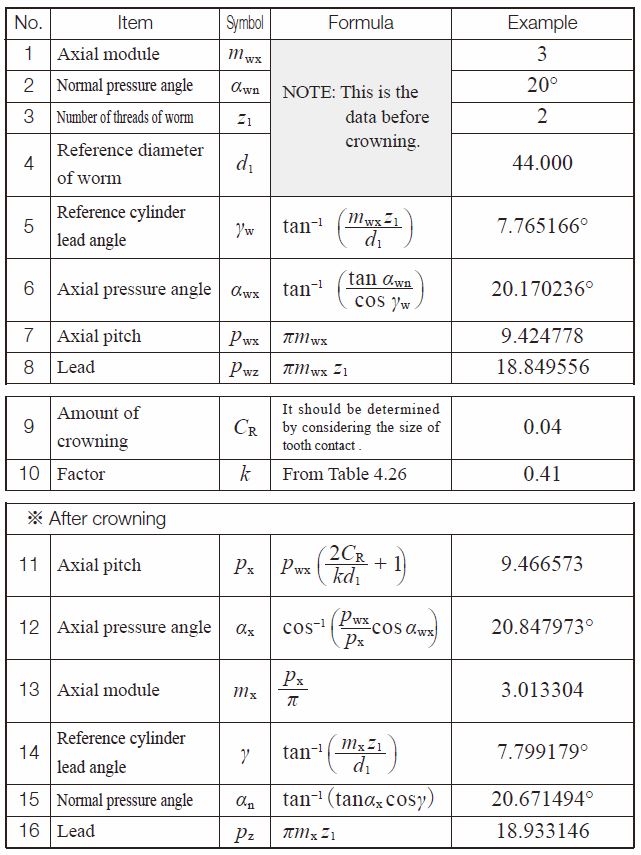

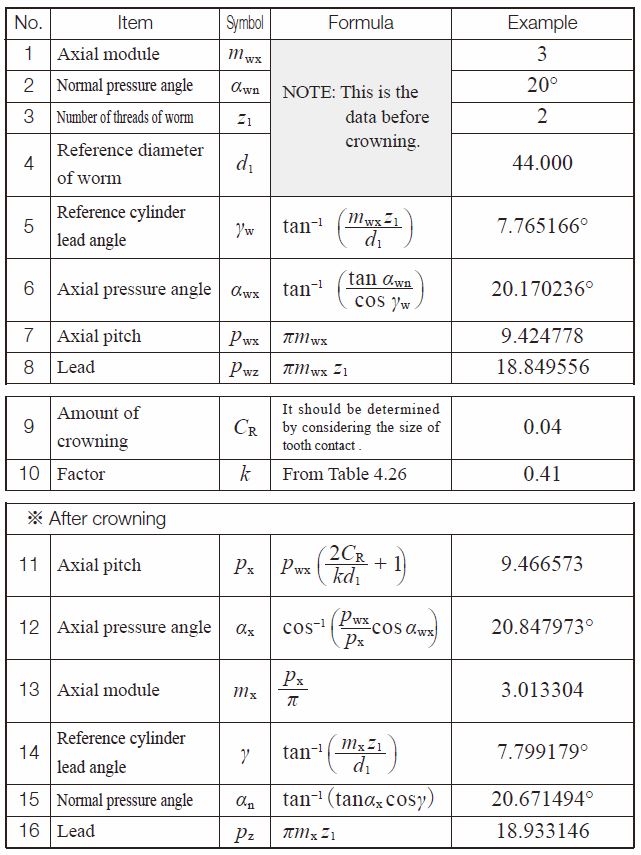

This is a very complex method, both theoretically and practically. Usually, the crowning is done to the worm wheel, but in this method the modification is on the worm. That is, to change the pressure angle and pitch of the worm without changing base pitch, in accordance with the relationships shown in Equations 4.25 :

In order to raise the pressure angle from before change, αwx, to after change, αx , it is necessary to increase the axial pitch, pwx, to a new value, px, per Equation (4.25). The amount of crowning is represented as the space between the worm and worm wheel at the meshing point A in Figure 4.22. This amount may be approximated by the following equation :

Where

d1 : Reference diameter of worm

k : Factor from Table 4.25 and Figure 4.21

Table 4.25 The value of factor k

Axial pressure angle αx

Fig. 4.21 The value of factor (k)

Table 4.26 shows an example of calculating worm crowning.

Table 4.26 The calculations for worm crowning

(4) Self-Locking Of Worm Gear Pairs

Self-locking is a unique characteristic of worm meshes that can be put to advantage. It is the feature that a worm cannot be driven by the worm wheel. It is very useful in the design of some equipment, such as lifting, in that the drive can stop at any position without concern that it can slip in reverse. However, in some situations it can be detrimental if the system requires reverse sensitivity, such as a servomechanism.

Self-locking does not occur in all worm meshes, since it requires special conditions as outlined here. In this analysis, only the driving force acting upon the tooth surfaces is considered without any regard to losses due to bearing friction, lubricant agitation, etc. The governing conditions are as follows :

Let Ft1 = tangential driving force of worm

Then,

Ft1 = Fn (cos αn sin γ – μ cos γ) (4.27)

If Ft1 > 0 then there is no self-locking effect at all. Therefore,

Ft1 ≤ 0 is the critical limit of self-locking.

Let αn in Equation (4.27) be 20°, then the condition:

Ft1 ≤ 0 will become :

(cos 20° sing – mcosg) ≤ 0

Figure 4.22 shows the critical limit of self-locking for lead angle g and coefficient of friction m. Practically, it is very hard to assess the exact value of coefficient of friction μ. Further, the bearing loss, lubricant agitation loss, etc. can add many side effects. Therefore, it is not easy to establish precise self-locking conditions.

However, it is true that the smaller the lead angle γ, the more likely the self-locking condition will occur.

Fig.4.22 Position A is the point of determining crowning amount

4.1 Spur Gears

Spur Gears are the simplest type of gear. The calculations for spur gears are also simple and they are used as the basis for the calculations for other types of gears. This section introduces calculation methods of standard spur gears, profile shifted spur gears, and linear racks. The standard spur gear is a non-profile-shifted spur gear.(1) Standard Spur Gear

Figure 4.1 shows the meshing of standard spur gears. The meshing of standard spur gears means the reference circles of two gears contact and roll with each other. The calculation formulas are in Table 4.1.

Fig. 4.1 The Meshing of Standard Spur Gears

( α = 20°, z1 = 12, z2 = 24, x1 = x2 = 0 )

Table 4.1 Calculations for Standard Spur Gears

NOTE 1 : The subscripts 1 and 2 of z1 and z2 denote pinion and gear

All calculated values in Table 4.1 are based upon given module m and number of teeth (z1 and z2). If instead, the module m, center distance a and speed ratio i are given, then the number of teeth, z1 and z2, would be calculated using the formulas as shown in Table 4.2.

Table 4.2 The Calculations for Number of Teeth

Note, that the number of teeth will probably not be integer values when using the formulas in Table 4.2. In this case, it will be necessary to resort to profile shifting or to employ helical gears to obtain as near a transmission ratio as possible.

(2) Profile Shifted Spur Gear

Figure 4.2 shows the meshing of a pair of profile shifted gears. The key items in profile shifted gears are the operating (working) pitch diameters (dw) and the working (operating) pressure angle (αw). These values are obtainable from the modified center distance and the following formulas :

Fig. 4.2 The Meshing of Profile Shifted Gears

( α = 20°, z1 = 12, z2 = 24, x1 = +0.6, x2 = +0.36 )

In the meshing of profile shifted gears, it is the operating pitch circle that is in contact and roll on each other that portrays gear action. Table 4.3 presents the calculations where the profile shift coefficient has been set at x1 and x2 at the beginning. This calculation is based on the idea that the amount of the tip and root clearance should be 0.25m.

Table 4.3 The Calculations for Profile Shifted Spur Gears (1)

A standard spur gear is, according to Table 4.3, a profile shifted gear with 0 coefficient of shift; that is , x1 = x2 = 0.

Table 4.4 is the inverse formula of items from 4 to 8 of Table 4.3.

Table 4.4 The Calculations for Profile Shifted Spur Gears (2)

There are several theories concerning how to distribute the sum of profile shift coefficient (x1 + x2) into pinion (x1) and gear (x2) separately. BSS (British) and DIN (German) standards are the most often used. In the example above, the 12 tooth pinion was given sufficient correction to prevent undercut, and the residual profile shift was given to the mating gear.

(3) Rack and Spur Gear

Table 4.5 presents the method for calculating the mesh of a rack and spur gear.

Figure 4.3 (1) shows the the meshing of standard gear and a rack. In this mesh, the reference circle of the gear touches the pitch line of the rack.

Figure 4.3 (2) shows a profile shifted spur gear, with positive correction xm, meshed with a rack. The spur gear has a larger pitch radius than standard, by the amount xm. Also, the pitch line of the rack has shifted outward by the amount xm.

Table 4.5 presents the calculation of a meshed profile shifted spur gear and rack. If the profile shift coefficient x1 is 0, then it is the case of a standard gear meshed with the rack.

Table 4.5 The calculations of dimensions of a profile shifted spur gear and a rack

One rotation of the spur gear will displace the rack l one circumferential length of the gear’s reference circle, per the formula :

The rack displacement, l, is not changed in any way by the profile shifting. Equation (4.2) remains applicable for any amount of profile shift.

Fig. 4.3 (1) The meshing of standard spur gear and rack

( α = 20°, z1 = 12, x1 = 0 )

Fig. 4.3 (2) The meshing of profile shifted spur gear and rack

( α = 20°, z1 = 12, x1 = + 0.6 )

4.2 Internal Gears

Internal Gears are composed of a cylindrical shaped gear having teeth inside a circular ring. Gear teeth of the internal gear mesh with the teeth space of a spur gear. Spur gears have a convex shaped tooth profile and internal gears have reentrant shaped tooth profile; this characteristic is opposite of Internal gears. Here are the calculations for the dimensions of internal gears and their interference.(1) Internal Gear Calculations

Figure 4.4 presents the mesh of an internal gear and external gear. Of vital importance is the working pitch diameters (dw) and working pressure angle (αw). They can be derived from center distance (a) and Equations (4.3).

Table 4.6 shows the calculation steps. It will become a standard gear calculation if x1 = x2 = 0.

Fig.4.4 The meshing of internal gear and external gear

( α = 20°, z1 = 16, z2 = 24, x1 = x2 = +0.5 )

Table 4.6 The calculations of a profile shifted internal gear and external gear (1)

If the center distance (a) is given, x1 and x2 would be obtained from the inverse calculation from item 4 to item 8 of Table 4.6. These inverse formulas are in Table 4.7.

Table 4.7 The calculations of profile shifted internal gear and external gear (2)

Pinion cutters are often used in cutting internal gears and external gears. The actual value of tooth depth and root diameter, after cutting, will be slightly different from the calculation. That is because the cutter has a profile shift coefficient. In order to get a correct tooth profile, the profile shift coefficient of cutter should be taken into consideration.

(2) Interference In Internal Gears

Three different types of interference can occur with internal gears: (a) Involute Interference, (b) Trochoid Interference, and (c) Trimming Interference.

(a) Involute Interference

This occurs between the dedendum of the external gear and the addendum of the internal gear. It is prevalent when the number of teeth of the external gear is small. Involute interference can be avoided by the conditions cited below :

Where αa2 is the pressure angle at a tip of the internal gear tooth.

αw:working pressure angle

Equation (4.5) is true only if the tip diameter of the internal gear is bigger than the base circle :

For a standard internal gear, where α = 20° , Equation (4.7) is valid only if the number of teeth is z2 > 34.

(b) Trochoid Interference

This refers to an interference occurring at the addendum of the external gear and the dedendum of the internal gear during recess tooth action. It tends to happen when the difference between the numbers of teeth of the two gears is small. Equation (4.8) presents the condition for avoiding trochoidal interference.

Here

where αa1 is the pressure angle of the spur gear tooth tip:

In the meshing of an external gear and a standard internal gear α = 20° , trochoid interference is avoided if the difference of the number of teeth, z2 – z1, is larger than 9.

(c) Trimming Interference

This occurs in the radial direction in that it prevents pulling the gears apart. Thus, the mesh must be assembled by sliding the gears together with an axial motion. It tends to happen when the numbers of teeth of the two gears are very close. Equation (4.11) indicates how to prevent this type of interference.

Here

This type of interference can occur in the process of cutting an internal gear with a pinion cutter. Should that happen, there is danger of breaking the tooling. Table 4.8 (1) shows the limit for the pinion cutter to prevent trimming interference when cutting a standard internal gear, with pressure angle α0 = 20°, and no profile shift, i.e., x0 = 0.

Table 4.8 (1) The limit to prevent an internal gear from trimming interference

There will be an involute interference between the internal gear and the pinion cutter if the number of teeth of the pinion cutter ranges from 15 to 22 (z0 = 15 to 22). Table 4.8(2) shows the limit for a profile shifted pinion cutter to prevent trimming interference while cutting a standard internal gear. The correction (x0) is the magnitude of shift which was assumed to be: x0 = 0.0075z0 + 0.05.

Table 4.8 (2) The limit to prevent an internal gear from trimming interference

There will be an involute interference between the internal gear and the pinion cutter if the number of teeth of the pinion cutter ranges from 15 to 19 (z0 = 15 to 19).

Fig.4.5 Involute interference and trochoid interference

Fig.4.6 Trimming interference

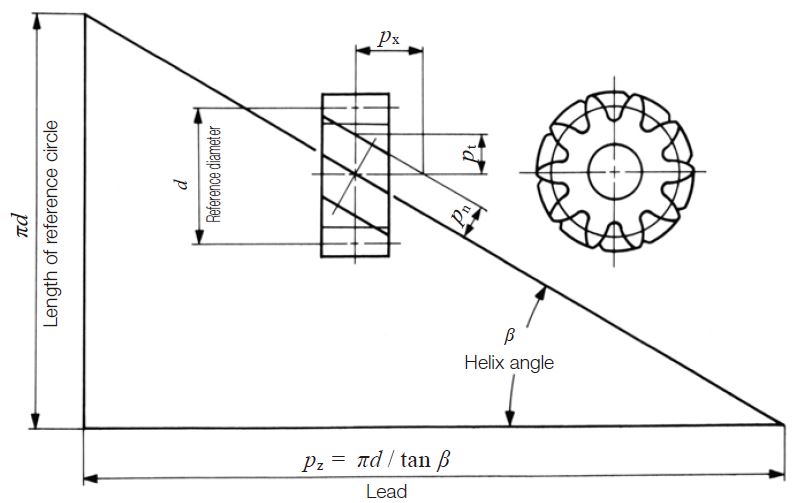

4.3 Helical Gears

A helical gear such as shown in Figure 4.7 is a cylindrical gear in which the teeth flank are helicoid. The helix angle in reference cylinder is β, and the displacement of one rotation is the lead, pz.The tooth profile of a helical gear is an involute curve from an axial view, or in the plane perpendicular to the axis. The helical gear has two kinds of tooth profiles – one is based on a normal system, the other is based on a transverse system.

Pitch measured perpendicular to teeth is called normal pitch, pn.

And pn divided by π is then a normal module, mn.

The tooth profile of a helical gear with applied normal module,

mn, and normal pressure angle αn belongs to a normal system.

In the axial view, the pitch on the reference is called the transverse pitch, pt . And pt divided by π is the transverse module, mt.

These transverse module mt and transverse pressure angle αt at are the basic configuration of transverse system helical gear.

In the normal system, helical gears can be cut by the same gear hob if module mn and pressure angle at are constant, no matter what the value of helix angle β.

It is not that simple in the transverse system. The gear hob design must be altered in accordance with the changing of helix angle β, even when the module mt and the pressure angle at are the same.

Obviously, the manufacturing of helical gears is easier with the normal system than with the transverse system in the plane perpendicular to the axis.

When meshing helical gears, they must have the same helix angle but with opposite hands.

Fig.4.7 Fundamental relationship of a helical gear (Right-hand)

(1) Normal System Helical Gear

In the normal system, the calculation of a profile shifted helical gear, the working pitch diameter dw and transverse working pressure angle αwt is done per Equations (4.15). That is because meshing of the helical gears in the transverse plane is just like spur gears and the calculation is similar.

Table 4.9 shows the calculation of profile shifted helical gears in the normal system. If normal profile shift coefficients xn1, xn2 are zero, they become standard gears.

Table 4.9 The calculations of a profile shifted helical gear in the normal system (1)

If center distance, α, is given, the normal profile shift coefficients xn1 and xn2 can be calculated from Table 4.10. These are the inverse equations from items 5 to 10 of Table 4.9.

Table 4.10 The calculations for a profile shifted helical gear in the normal system (2)

The transformation from a normal system to a transverse system is accomplished by the following equations :

(2) Transverse System Helical Gear

Table 4.11 shows the calculation of profile shifted helical gears in a transverse system. They become standard if xt1 = xt2 = 0.

Table 4.11 The calculations for a profile shifted helical gear in the transverse system (1)

Table 4.12 presents the inverse calculation of item 5 to 9 of Table 4.11.

Table 4.12 The calculations for a profile shifted helical gear in the transverse system (2)

The transformation from a transverse to a normal system is described by the following equations :

(3) Helical Rack

Viewed in the transverse plane, the meshing of a helical rack and gear is the same as a spur gear and rack. Table 4.13 presents the calculation examples for a mated helical rack with normal module and normal pressure angle. Similarily, Table 4.14 presents examples for a helical rack in the transverse system (i.e., perpendicular to gear axis).

Table 4.13 The calculations for a helical rack in the normal system

The formulas of a standard helical rack are similar to those of Table 4.14 with only the normal profile shift coefficient xn = 0.

To mesh a helical gear to a helical rack, they must have the same helix angle but with opposite hands.

The displacement of the helical rack, l, for one rotation of the mating gear is the product of the transverse pitch and number of teeth.

According to the equations of Table 4.13, let transverse pitch pt = 8 mm and displacement l = 160 mm. The transverse pitch and the displacement could be resolved into integers, if the helix angle were chosen properly.

Table 4.14 The calculations for a helical rack in the transverse system

In the meshing of transverse system helical rack and helical gear, the movement, l, for one turn of the helical gear is the transverse pitch multiplied by the number of teeth.

4.4 Bevel Gears

Bevel gears, whose pitch surfaces are cones, are used to drive intersecting axes. Bevel gears are classified according to their type of the tooth forms into Straight Bevel Gear, Spiral Bevel Gear, Zerol Bevel Gear, Skew Bevel Gear etc. The meshing of bevel gears means the pitch cone of two gears contact and roll with each other. Let z1 and z2 be pinion and gear tooth numbers; shaft angle Σ ; and reference cone angles δ1 and δ2 ; then:

Fig. 4.8 The reference cone angle of bevel gear

Generally, a shaft angle Σ = 90° is most used. Other angles (Figure 4.8) are sometimes used. Then, it is called “bevel gear in nonright angle drive”. The 90° case is called “bevel gear in right angle drive”. When Σ = 90°, Equation (4.20) becomes :

Miter gears are bevel gears with Σ = 90° and z1 = z2. Their transmission ratio z2 / z1 = 1.

Figure 4.9 depicts the meshing of bevel gears. The meshing must be considered in pairs. It is because the reference cone angles δ1 and δ2 are restricted by the gear ratio z2 / z1. In the facial view, which is normal to the contact line of pitch cones, the meshing of bevel gears appears to be similar to the meshing of spur gears.

Fig. 4.9 The meshing of bevel gears

(1) Gleason Straight Bevel Gears

A straight bevel gear is a simple form of bevel gear having straight teeth which, if extended inward, would come together at the intersection of the shaft axes. Straight bevel gears can be grouped into the Gleason type and the standard type.

In this section, we discuss the Gleason straight bevel gear. The Gleason Company defines the tooth profile as: tooth depth h = 2.188m; tip and root clearance c = 0.188m; and working depth hw = 2.000m.

The characteristics are :

** Design specified profile shifted gears

In the Gleason system, the pinion is positive shifted and the gear is negative shifted. The reason is to distribute the proper strength between the two gears. Miter gears, thus, do not need any shift.

** The tip and root clearance is designed to be parallel

The face cone of the blank is turned parallel to the root cone of the mate in order to eliminate possible fillet interference at the small end of the teeth.

Fig. 4.10 Dimensions and angles of bevel gears

Table 4.15 shows the minimum number of the teeth to prevent undercut in the Gleason system at the shaft angle Σ = 90.°

Table 4.15 The minimum numbers of teeth to prevent undercut

Table 4.16 presents equations for designing straight bevel gears in the Gleason system. The meanings of the dimensions and angles are shown in Figure 4.10 above. All the equations in Table 4.16 can also be applied to bevel gears with any shaft angle.

The straight bevel gear with crowning in the Gleason system is called a Coniflex gear. It is manufactured by a special Gleason “Coniflex” machine. It can successfully eliminate poor tooth contact due to improper mounting and assembly.

Tale 4.16 The calculations of straight bevel gears of the Gleason system

The first characteristic of a Gleason Straight Bevel Gear that it is a profile shifted tooth. From Figure 4.11, we can see the tooth profile of Gleason Straight Bevel Gear and the same of Standard Straight Bevel Gear.

Fig. 4.11 The tooth profile of straight bevel gears

(2) Standard Straight Bevel Gears

A bevel gear with no profile shifted tooth is a standard straight bevel gear. The are also referred to as Klingelnberg bevel gears. The applicable equations are in Table 4.17.

Table 4.17 The calculations for a standard straight bevel gears

These equations can also be applied to bevel gear sets with other than 90° shaft angles.

(3) Gleason Spiral Bevel Gears

A spiral bevel gear is one with a spiral tooth flank as in Figure 4.12. The spiral is generally consistent with the curve of a cutter with the diameter dc. The spiral angle β is the angle between a generatrix element of the pitch cone and the tooth flank. The spiral angle just at the tooth flank center is called the mean spiral angle βm. In practice, the term spiral angle refers to the mean spiral angle.

Fig.4.12 Spiral Bevel Gear (Left-hand)

All equations in Table 4.20 are specific to the manufacturing method of Spread Blade or of Single Side from Gleason. If a gear is not cut per the Gleason system, the equations will be different from these.

The tooth profile of a Gleason spiral bevel gear shown here has the tooth depth h = 1.888m; tip and root clearance c = 0.188m; and working depth hw = 1.700m. These Gleason spiral bevel gears belong to a stub gear system. This is applicable to gears with modules m > 2.1.

Table 4.18 shows the minimum number of teeth to avoid undercut in the Gleason system with shaft angle Σ = 90° and pressure angle αn = 20°.

Table 4.18 The minimum numbers of teeth to prevent undercut β=35°

If the number of teeth is less than 12, Table 4.19 is used to determine the gear sizes.

Table 4.19 Dimentions for pinions with number of teeth less than 12

Table 4.20 shows the calculations for spiral bevel gears in the Gleason system

Table 4.20 The calculations for spiral bevel gears in the Gleason system

All equations in Table 4.20 are also applicable to Gleason bevel gears with any shaft angle. A spiral bevel gear set requires matching of hands; left-hand and right-hand as a pair.

(4) Gleason Zerol Bevel Gears

When the spiral angle bm = 0, the bevel gear is called a Zerol bevel gear. The calculation equations of Table 4.16 for Gleason straight bevel gears are applicable. They also should take care again of the rule of hands; left and right of a pair must be matched. Figure 4.13 is a left-hand Zerol bevel gear.

Fig. 4.13 Left-hand zerol bevel gear

4.5 Screw Gears

Screw gearing includes various types of gears used to drive nonparallel and nonintersecting shafts where the teeth of one or both members of the pair are of screw form. Figure 4.14 shows the meshing of screw gears. Two screw gears can only mesh together under the conditions that normal modules (mn1) and (mn2) and normal pressure angles (αn1, αn2) are the same.Fig.4.14 Screw gears of nonparallel and nonintersecting axes

Let a pair of screw gears have the shaft angle Σ and helix angles β1 and β2 :

If the screw gears were profile shifted, the meshing would become a little more complex. Let βw1, βw2 represent the working pitch cylinder ;

Table 4.21 presents equations for a profile shifted screw gear pair. When the normal profile shift coefficients xn1 = xn2 = 0, the equations and calculations are the same as for standard gears.

Table 4.21 The equations for a screw gear pair on nonparallel and Nonintersecting axes in the normal system

Standard screw gears have relations as follows:

dw1 = d1

dw2 = d2

βw1 = β1

βw2 = β2

(4.24)

4.6 Cylindrical Worm Gear Pair

Cylindrical worms may be considered cylindrical type gears with screw threads. Generally, the mesh has a 90° shaft angle. The number of threads in the worm is equivalent to the number of teeth in a gear of a screw type gear mesh. Thus, a onethread worm is equivalent to a one-tooth gear; and two-threads equivalent to two-teeth, etc. Referring to Figure 4.15, for a reference cylinder lead angle γ, measured on the pitch cylinder, each rotation of the worm makes the thread advance one lead pz.There are four worm tooth profiles in JIS B 1723-1977, as defined below.

Type I : The tooth profile is trapezoidal on the axial plane.

Type II : The tooth profile is trapezoid on the plane normal to the space.

Type III : The tooth profile which is obtained by inclining the axis of the milling or grinding, of which cutter shape is trapezoidal on the cutter axis, by the lead angle to the worm axis.

Type IV : The tooth profile is of involute curve on the plane of rotation.

KHK stock worm gear products are all Type III. Worm profiles (Fig 4.15). The cutting tool used to process worm gears is called a single-cutter that has a single-edged blade. The cutting of worm gears is done with worm cutting machine. Because the worm mesh couples nonparallel and nonintersecting axes, the axial plane of worm does not correspond with the axial plane of worm wheel. The axial plane of worm corresponds with the transverse plane of worm wheel. The transverse plane of worm corresponds with the axial plane of worm wheel. The common plane of the worm and worm wheel is the normal plane. Using the normal module, mn, is most popular. Then, an ordinary hob can be used to cut the worm wheel.

Fig. 4.15 Cutting – Grinding for Type III Worm

Table 4.22 presents the relationships among worm and worm wheel with regard to axial plane, transverse plane, normal plane, module, pressure angle, pitch and lead.

Fig. 4.16 Cylindrical worm (Right-hand)

Table 4.22 The relations of cross sections of worm gear pairs

Reference to Figure 4.16 can help the understanding of the relationships in Table 4.22. They are similar to the relations in Formulas (4.16) and (4.17) in that the helix angle β be substituted by (90 deg – γ). We can consider that a worm with lead angle γ is almost the same as a helical gear with helix angle (90 deg – γ).

(1) Axial Module Worm Gear Pair

Table 4.23 presents the equations, for dimensions shown in Figure 4.16, for worm gears with axial module, mx, and normal pressure angle αn = 20°.

Fig. 4.17 Dimentions of cylindrical worm gear pair

Table 4.23 The calculations for an axial module system worm gear pair

NOTE 1.

Diameter factor, Q, means reference diameter of worm, d1, over axial module, mx.

Q = d1 / mx

NOTE 2.

There are several calculation methods of worm wheel tip diameter da2 besides those in Table 4.25.

NOTE 3.

The facewidth of worm, b1, would be sufficient if: b1 = πmx (4.5 + 0.02z2)

NOTE 4.

Effective facewidth of worm wheel bw =

So the actual facewidth of b2 ≧ bw + 1.5mx would be enough.

(2) Normal Module System Worm Gear Pair

The equations for normal module system worm gears are based on a normal module, mn, and normal pressure angle, αn = 20°. See Table 4.24.

Table 4.24 The calculations for a normal module system worm gear pair

NOTE : All notes are the same as those of Table 4.23.

(3) Crowning of the Tooth

Crowning is critically important to worm gears. Not only can it eliminate abnormal tooth contact due to incorrect assembly, but it also provides for the forming of an oil film, which enhances the lubrication effect of the mesh. This can favorably impact endurance and transmission efficiency of the worm mesh. There are four methods of crowning worm gear pair :

(a) Cut Worm Wheel with a Hob Cutter of Greater Reference Diameter than the Worm.

A crownless worm wheel results when it is made by using a hob that has an identical pitch diameter as that of the worm. This crownless worm wheel is very difficult to assemble correctly. Proper tooth contact and a complete oil film are usually not possible.

However, it is relatively easy to obtain a crowned worm wheel by cutting it with a hob whose reference diameter is slightly larger than that of the worm.

This is shown in Figure 4.18. This creates teeth contact in the center region with space for oil film formation.

Fig.4.18 The method of using a greater diameter hob

(b) Recut With Hob Center Position Adjustment.

The first step is to cut the worm wheel at standard center distance. This results in no crowning. Then the worm wheel is finished with the same hob by recutting with the hob axis shifted parallel to the worm wheel axis by ±Δh. This results in a crowning effect, shown in Figure 4.19.

Fig.4.19 Offsetting up or down

(c) Hob Axis Inclining Δθ From Standard Position.

In standard cutting, the hob axis is oriented at the proper angle to the worm wheel axis. After that, the hob axis is shifted slightly left and then right, Δθ, in a plane parallel to the worm wheel axis, to cut a crown effect on the worm wheel tooth.

This is shown in Figure 4.20. Only method (a) is popular. Methods (b) and (c) are seldom used.

Fig. 4.20 Inclining right or left

(d) Use a Worm with a Larger Pressure Angle than the Worm Wheel.

This is a very complex method, both theoretically and practically. Usually, the crowning is done to the worm wheel, but in this method the modification is on the worm. That is, to change the pressure angle and pitch of the worm without changing base pitch, in accordance with the relationships shown in Equations 4.25 :

In order to raise the pressure angle from before change, αwx, to after change, αx , it is necessary to increase the axial pitch, pwx, to a new value, px, per Equation (4.25). The amount of crowning is represented as the space between the worm and worm wheel at the meshing point A in Figure 4.22. This amount may be approximated by the following equation :

Where

d1 : Reference diameter of worm

k : Factor from Table 4.25 and Figure 4.21

Table 4.25 The value of factor k

Axial pressure angle αx

Fig. 4.21 The value of factor (k)

Table 4.26 shows an example of calculating worm crowning.

Table 4.26 The calculations for worm crowning

(4) Self-Locking Of Worm Gear Pairs

Self-locking is a unique characteristic of worm meshes that can be put to advantage. It is the feature that a worm cannot be driven by the worm wheel. It is very useful in the design of some equipment, such as lifting, in that the drive can stop at any position without concern that it can slip in reverse. However, in some situations it can be detrimental if the system requires reverse sensitivity, such as a servomechanism.

Self-locking does not occur in all worm meshes, since it requires special conditions as outlined here. In this analysis, only the driving force acting upon the tooth surfaces is considered without any regard to losses due to bearing friction, lubricant agitation, etc. The governing conditions are as follows :

Let Ft1 = tangential driving force of worm

Then,

Ft1 = Fn (cos αn sin γ – μ cos γ) (4.27)

If Ft1 > 0 then there is no self-locking effect at all. Therefore,

Ft1 ≤ 0 is the critical limit of self-locking.

Let αn in Equation (4.27) be 20°, then the condition:

Ft1 ≤ 0 will become :

(cos 20° sing – mcosg) ≤ 0

Figure 4.22 shows the critical limit of self-locking for lead angle g and coefficient of friction m. Practically, it is very hard to assess the exact value of coefficient of friction μ. Further, the bearing loss, lubricant agitation loss, etc. can add many side effects. Therefore, it is not easy to establish precise self-locking conditions.

However, it is true that the smaller the lead angle γ, the more likely the self-locking condition will occur.

Fig.4.22 Position A is the point of determining crowning amount